We recap the top five most-read blog articles of 2018. The variation in topics shows we've got a diverse group of clients and readers, and their interests reflect a shift in the industrial sector towards industry 4.0 and Internet of Things (IoT), while remaining committed to plant maintenance and reliability.

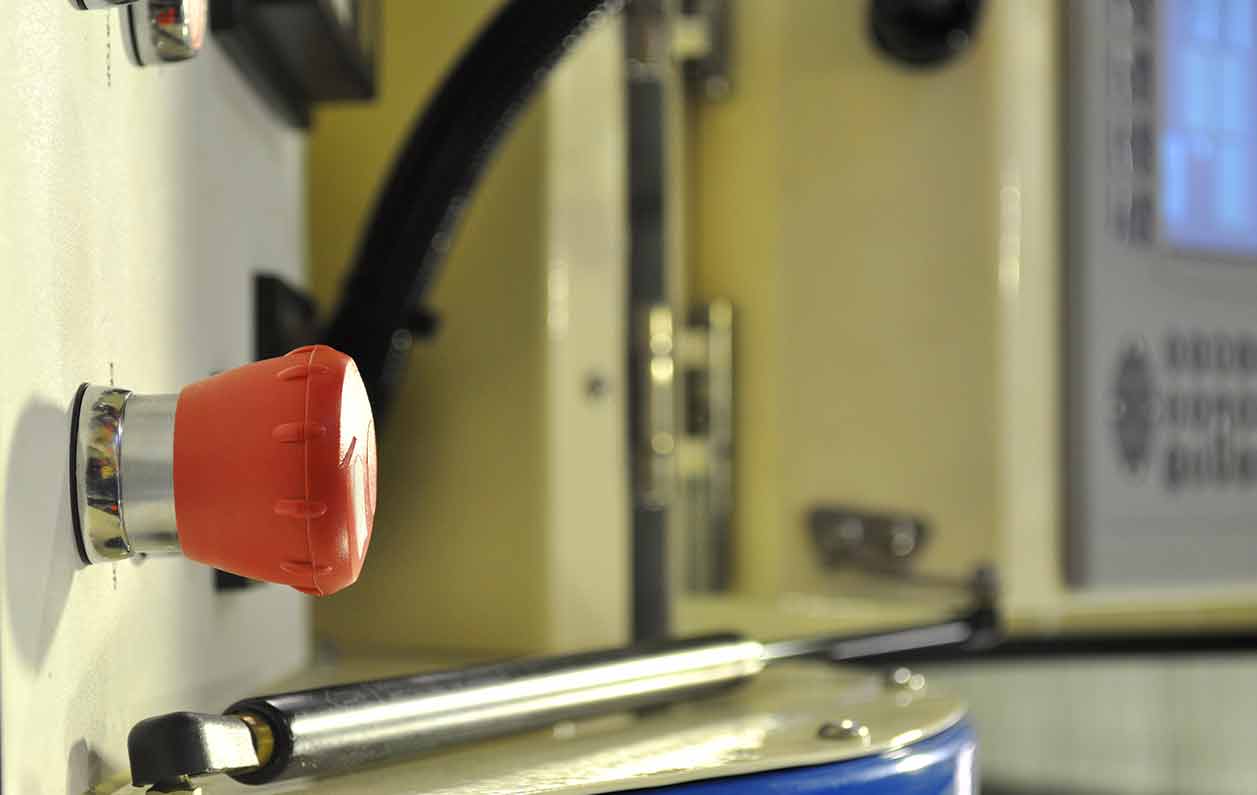

Whether you want to take advantage of a seasonal shut down, or are just looking to review your facility's maintenance throughout the year, this list will help you concentrate your efforts on the most essential facility maintenance on your control systems.

Talk about the Internet of things (IoT), and its ability to bring unparalleled efficiencies to all industries is intensifying.

Given the manufacturing industry accounts for eighteen per cent of Australia’s energy consumption, it has the most to gain from implementing energy saving improvements.

Australia’s peak business group leaders have recently stepped up their encouragement of companies to embrace automation, as statistics show the nation is trailing other advanced economies on the road towards Industry 4.0.

If you’ve been asked to improve your businesses’ energy efficiency in a bid to reduce electricity bills, you’ll likely have considered power factor correction.

While Australian manufacturers understand the benefits of Industry 4.0, many are still in the early stages of ‘digital maturity’.

The Australian water industry is facing new and old challenges. Industry 4.0 – with its promise of increased visibility and performance with data – presents the solution.

How can you obtain and manage data without the high costs of building and hosting a traditional supervisory control and data acquisition (SCADA) system? With nearly everything else going into a cloud-based service, we asked ourselves, “Why not SCADA?”