For owners and managers of industrial facilities, optimising asset performance in a dynamic and complex operation environment is a constant challenge—trying to maximise performance while maintaining operational flexibility.

Incorporating smart tunnel solutions provides road authorities with the greatest opportunity to make existing and future tunnels safer and more cost-effective. Future-proofing our road networks has always been SAGE Automation’s goal, and congestion management is just one part of this.

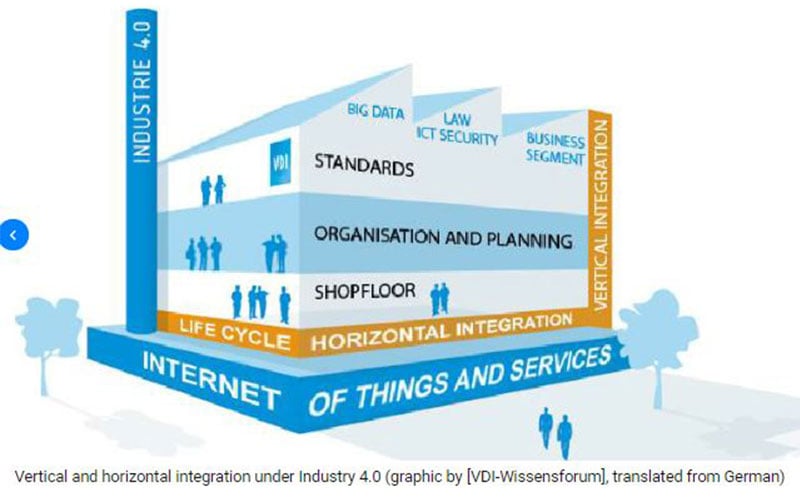

For more than thirty years, companies have widely adopted a Lean manufacturing mindset to continuously improve their operations. Now with the merger of digital and physical systems as part of the Industry 4.0 transition, businesses can use both ideas concepts to take operational excellence to a new level.

While some are still reading about the value of industry 4.0, other industrial operators are already taking advantage of new technologies that are reducing their risk of extended downtime through fast response, support and prevention.

It sounds like a sci-fi movie plot: your doppelgänger lives in another dimension and behaves exactly like you, but learns faster and can access more information. It’s the ‘test dummy’ that tries everything first, so you can make all the right decisions to lead a perfect life.

Whether you want to take advantage of a seasonal shut down, or are just looking to review your facility's maintenance throughout the year, this list will help you concentrate your efforts on the most essential facility maintenance on your control systems.

Industry continues to face increasing pressure in the management of capital assets: shrinking budgets, increased performance expectations, and evermore regulatory oversight.

In large scale operations or small workshop environments the right manufacturing maintenance KPIs can have enormous impact on operability and maintainability.

Manufacturers face a daunting task. They’re expected to achieve increasingly short production time frames, while still meeting quality, safety and compliance standards… It’s a big ask, to say the least.