At SAGE we are continually seeking out better ways to deliver efficiency for our customers. We identified an opportunity to transform how parts are stored and retrieved in our Advanced Manufacturing Facility and the Lean Lift was developed.

While there has always been innovation in the defence industry, the race is on for their supply chain partners to adopt Industry 4.0 technologies.

Defence organisations are always facing new challenges.

As the implementation of industry 4.0 technologies becomes a reality for more and more manufacturers, the full potential benefits these advancements have for the defence supply chain have yet to be realised.

Councils are increasingly seeking out smarter asset management methods that improve resource allocation and ultimately public services.

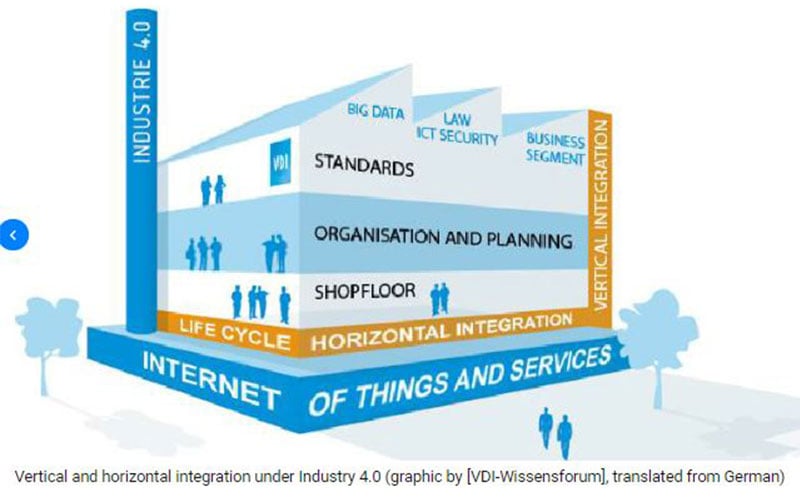

For more than thirty years, companies have widely adopted a Lean manufacturing mindset to continuously improve their operations. Now with the merger of digital and physical systems as part of the Industry 4.0 transition, businesses can use both ideas concepts to take operational excellence to a new level.

While some are still reading about the value of industry 4.0, other industrial operators are already taking advantage of new technologies that are reducing their risk of extended downtime through fast response, support and prevention.

It sounds like a sci-fi movie plot: your doppelgänger lives in another dimension and behaves exactly like you, but learns faster and can access more information. It’s the ‘test dummy’ that tries everything first, so you can make all the right decisions to lead a perfect life.

We’ve been beating the industry 4.0 drum loudly to our clients for some time. And for good reason – we’ve seen first-hand how clients are benefiting from increased visibility, data probity and response time across utilities, transport, and smart manufacturing.