How defence equipment manufacturers can elevate your offering with Industry 4.0 initiatives

SAGE Automation, Published: September 19, 2019 - Updated: February 15, 2026 (10 min read)

Defence organisations are always facing new challenges.

The complexity of the assets they require means the Australian defence industry is in need of manufacturers with advanced capabilities. Primes are under more pressure to find defence equipment manufacturers who can collaborate and produce world-leading products with slimmer budgets. The defence supply chain is being encouraged to transform their thinking to project collaboration, not competition.

It’s easy to think this has the potential to be a gloom-and-doom scenario, but with the rise of Industry 4.0 initiatives, Australian manufacturing is in a much better position than it has been in the last few decades.

Defence equipment manufacturing with industry 4.0 initiatives

In a previous blog, we outlined some of the key benefits industry 4.0 initiatives can have for improving the offering to the Australian defence industry. While using this technology may be the focus of your business, finding the right supply chain partner provides the most assurance that you can access the benefits while minimising disruptions to operations.

To help more defence primes and OEMs to take advantage of industry 4.0 initiatives, we’ve outlined some of the things you should look for to find the right defence supply chain partner.

Problem: tighter budgets make it harder to keep up with technological advancements

While the 2016 Defence White Paper made a commitment to increase the Australian defence budget to 2% GDP by 2020-21, the defence industry’s ongoing challenge is having to spread itself further to support growing needs. As Defence Connect outlines, the increase of defence responsibilities and capabilities is always expanding; this places added pressure on defence primes to deliver better capabilities in less time. Add a tight budget and a need for sovereign support capabilities for defence into the equation and there is a lot riding on each project.

Solution: working with defence equipment manufacturers who can optimise production and reduce costs

Cost has always been a factor that influenced the selection of defence equipment manufacturers. An advanced manufacturer with defence industry experience is a way defence primes can access the market for a lower cost and take advantage of industry 4.0 technology without the need for capital investment. Partnering with these experts can bring more flexibility and efficiency to manufacturing needs, allowing for defence primes and OEMs to become more competitive on price.

For SAGE Automation, we’ve seen first-hand how these advanced technologies can make a huge difference in the manufacturing process, speeding up production time and allowing for greater scalability. Through integrating 3D CAD and the digital twin, control panels can be replicated faster and with more reliability, delivering more cost-effective and consistent products for end clients.

Through the use of advanced technologies and the ability to enhance production, such as by digitally replicating processes or systems, comes improved risk management for defence suppliers. With the digital twin, for example, there is no need to physically build a prototype when developing or changing a product. Instead, the digital profile allows for simulation, so product modifications can be tested to see what affect they will have on performance or quality. This allows for design modifications and customer feedback to be drawn into the process without having a substantial impact on the cost and on the rest of the supply chain.

What to look for: an advanced manufacturer investing in industry 4.0 initiatives.

Problem: scheduling and meeting deadlines with multiple stakeholders

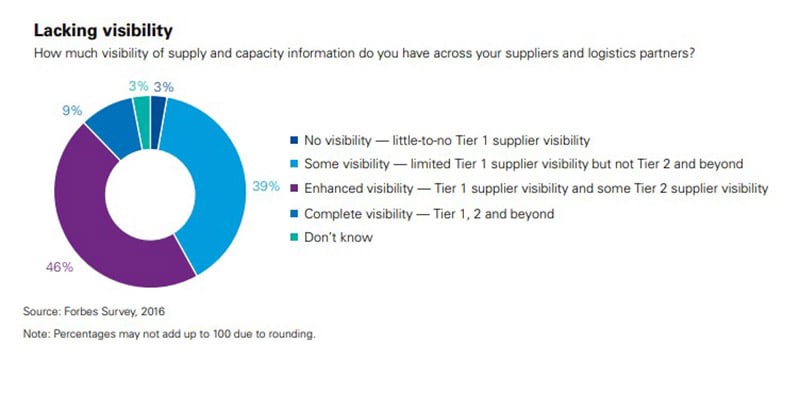

The complexity and sheer number of stakeholders involved in defence supply chains can make coordination and visibility over projects a challenge. The linear nature of supply chain workflow means that if an issue or a change in design happens at any stage, it has a flow-on effect for every process that follows, eventually compounding with delays for the end user. Scheduled completion dates can be missed as a result. A 2016 survey conducted by KPMG found that 87% of respondents cited supply chain failure as a major threat to achieving their growth agenda.

KPMG's 2016 survey highlighted that larger OEMs and defence contractors struggled with lack of visibility in the supply chain.

In the defence industry, outsourcing can make scheduling and getting status information harder. Without visibility over the many arms of the supply chain, there will always be the risk of missing crucial delivery dates or having a product manufactured that no longer meets the design specifications.

On top of these scheduling concerns, ensuring compliance when there are multiple stakeholders involved in the product design and manufacturing process can be a challenge. Becoming certified in standards such as ISO 9001 is a complex process in itself, according to Defence Connect.

Solution: find a defence equipment manufacturer who allows for greater transparency during production

The best way to overcome these issues is by finding a supply chain partner who is already making use of industry 4.0 technologies, whether that is through digital record-keeping or additive manufacturing to quickly create customised products.

The ability to share information across the supply network can dramatically improve the speed of production and allow defence primes to regularly see the status of a piece of equipment.

An example of this, as McKinsey explains, is:

“an engine maker can share three-dimensional models of component design within its network, and each supplier in turn can share information about price, delivery and quality. This type of information sharing and transparency reduces the labour required to manage design changes, reduces risk for the [engine] maker and suppliers and speeds changes across the supply network.”

For a company like SAGE, which has fully integrated design and manufacturing capabilities in-house, the digital twin has enhanced the ability to share information with stakeholders in the supply chain. Stakeholder insight can feed into the production process at almost any stage, allowing for recommendations to be made along the way – with everything fully documented. This means any design issues can be quickly resolved without compromising the final product, inventory can be easily managed and delivery timeframes are available in real time. Despite this transparency with suppliers, SAGE takes measures to ensure the classification and security of data for defence customers — a vital consideration for manufacturers working with the defence industry.

3D CAD and the digital twin have allowed manufacturers like SAGE to speed up production time and allow greater scalability.

3D CAD and the digital twin have allowed manufacturers like SAGE to speed up production time and allow greater scalability.

Industry 4.0 initiatives provide defence primes with real-time visibility and greater control during manufacturing, as well as making it easier to meet compliancy requirements. SAGE has previously delivered complete project management services to defence primes, which included safety and risk assessment work for electrical designs for multiple Mobile Control and Reporting Centres.

What to look for: a defence manufacturing partner with an understanding of Australian compliance requirements and appropriate classification initiatives.

Problem: gathering the right project knowledge

Locating and recruiting people with domain knowledge has long been a challenge in many industries. When it comes to complex projects in defence, there is often a limited pool of expertise as training may not be fast enough to meet the required demand. Defence primes and OEMs often rely on contractors to fill gaps in their knowledge, which can make it difficult to retain these skillsets long-term.

Even with the Australian Government investment in workforce skills to suit the defence industry, such as advanced manufacturing, ICT and engineering, there is still a long lead time before those skills become available.

Solution: utilise SMEs from the defence supply chain

It might sound surprising but the reality is most defence primes could not justify the need for extensive niche knowledge to be retained internally for the small number of times their skills may be needed. Many hard-to-find skills, such as those in cyber security or automation, can be part of the offering from the supply chain network, particularly for those with maturity in defence projects.

The ability to bring together knowledge is something SAGE has already demonstrated when working onboard the HMAS Canberra and HMAS Adelaide. Being able to draw on the abilities of teams with HVAC, communications, hydraulics and electrical knowledge assisted with conducting set-to-work commissioning of I/O points and delivered training that maximises the value of the technology SAGE helps to develop. This wide range of technical knowledge streamlines processes and can help to de-risk complex projects — as well as making it easier to meet documentation requirements. Having this supply chain expertise can also be crucial for asset management, particularly in terms of through life support.

Another advantage of accessing extensive domain knowledge from your supply chain network is the ability to tap into experience in other sectors that may not seem defence-aligned. This can be hugely beneficial for finding solutions and when planning for defence compliance.

What to look for: a partner with end-to-end project capabilities and defence compliance knowledge.

Integrating Industry 4.0 initiatives through the defence manufacturing supply chain

The rise in advanced manufacturing capabilities has so much potential to overcome defence challenges, but it is dependent on finding the right partner in the supply chain.

With tighter market conditions, opportunities to optimise production are elevating suppliers into contracts that they may not have been considered for previously. Being able to collaborate with stakeholders and to demonstrate agility in manufacturing have become two of the most valuable traits for the defence supply chain.

SAGE has a long history of delivering collaborative technical solutions that meet stringent defence compliance standards. With the ability to provide reliable, large-scale manufacturing services to the defence force, SAGE is recognised as a trusted partner is the supply chain.

You can read more about SAGE’s ability to collaborate and fulfil orders for defence in this article, where the team built more than 160 control panels for the auxiliary oil replenishment ships for the Royal Australian Navy.