SAGE Automation's top 5 blogs of 2018

SAGE Automation, Published: January 3, 2019 - Updated: February 15, 2026 (7 min read)

We recap the top five most-read blog articles of 2018. The variation in topics shows we've got a diverse group of clients and readers, and their interests reflect a shift in the industrial sector towards industry 4.0 and Internet of Things (IoT), while remaining committed to plant maintenance and reliability.

Summary: The top blog post shows that industrial professionals remain keenly interested in getting the most performance out of their people and operations, with maintainability and downtime reduction being most popular topics. But manufacturing hasn't stolen the show. Our readers are also watching the transportation disruption and learning about the communication networks and technologies that will enable industry 4.0.

Finally, the top blogs show that skills and workforce development remain a big focus for professionals. In particular they resonated with the article on how SCADA will be relevant as jobs change in the age of big data.

So here they are, SAGE's most-read blogs of 2018 in order of popularity:

1. Developing powerful KPIs for manufacturing maintenance

At number one, SA Service Manager Pete Thompson outlines the steps to developing Key Performance Indicators for manufacturing maintenance programs.

Effective KPIs should help pinpoint the root cause of failure, understand where production losses occur and understand how effective your maintenance programs are. He says that maintenance itself can be judged in two ways: ‘doing the right maintenance’ or ‘doing maintenance right’.

In summary: choose what you want to measure, pick KPIs carefully, set benchmarks to aim for, and ensure you have a good data collection method.

Read the full article here: How to develop powerful KPIs for manufacturing maintenance

2. We're on the cusp of the biggest transport disruption in history: here's why

Autonomous vehicles are projected to change not only the way we get around, but also our environment and public spaces. It's no wounder that our article on how this disruption is occurring, was a popular one.

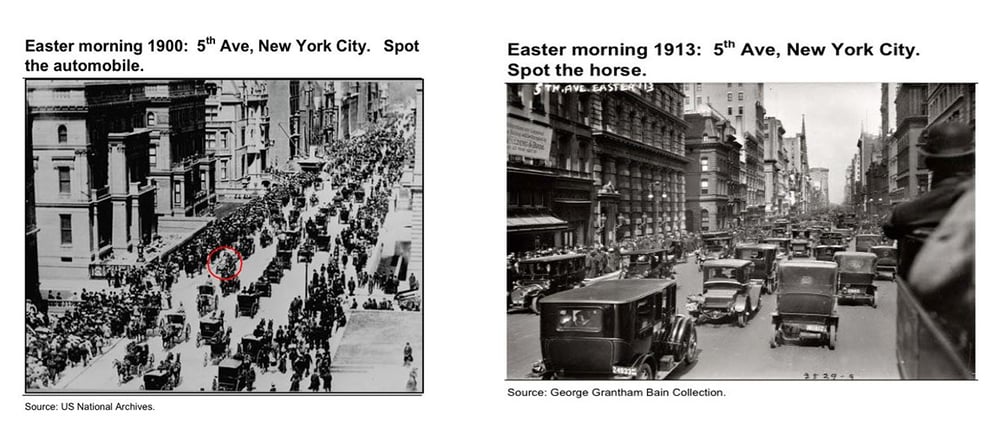

Our National Transport Manager Damian Hewitt begins the story with some history: "More than a century ago New York City went from all horses to cars from 1900-1913. This transport disruption only took 13 years!"

A combination of technology, business model innovation (think Uber), energy market change and the IoT is driving the autonomous vehicle transport disruption.

Read the full article here: We're on the cusp of the biggest transport disruption in history: here's why

3. Who will need SCADA training in the future?

Coming in at number three, this blog resonated with readers because it outlined some obvious, and not so obvious areas of demand for SCADA skills.

We identified three critical groups that need to be skilled in Supervisory Control and Data Acquisition (SCADA) systems as industry 4.0 changes the way we work. These are:

- engineers and operations/asset managers

- electricians and maintenance technicians

- IT professionals

Skills Lab General Manager Laura Mabikafola explains:

Digitisation and the Industrial Internet of Things is disrupting how we view and handle SCADA. Cloud based SCADA systems are already being used widely, and this means IT processionals will need to be proficient in both IT-based protocols and systems and SCADA."

Read the full article here: Who will need SCADA training in the future?

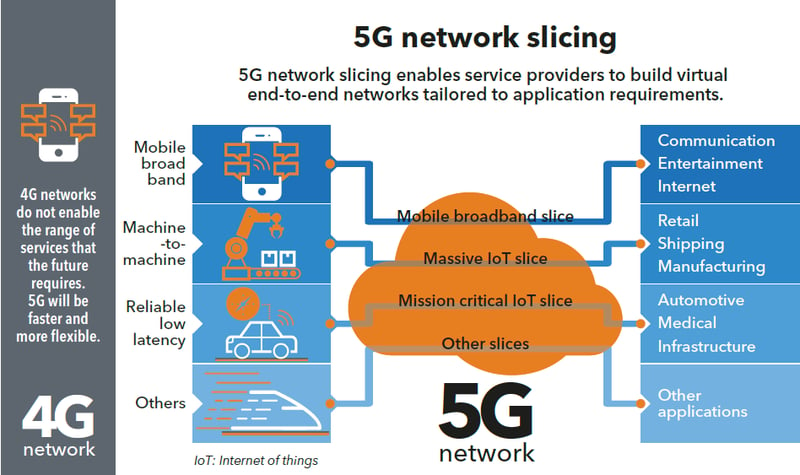

4. Why we're excited about the 5G network and how it will enable Industry 4.0

It seems everyone is talking about 5G, and everyone is interested. 5G is one of the communication networks from which the major technological disruptors of the century will scale.

This article explained what 5G is and why it is superior. 5G's high latency and availability as well as the ability to do network splicing and mesh networks means it can allow for things like autonomous vehicles, smart cities IoT initiatives and smart factories.

ITU Secretary-General, Houlin Zhao explains:

[5G] will be the global cornerstone for all activities related to broadband communications and the Internet of Things (IoT) for the future – enriching lives in ways yet to be imagined.”

Read the full article here: Why we're excited about the 5G network and how it will enable Industry 4.0

5. Manufacturing maintenance tips: 5 Factors that affect maintainability

At number five, we have another article focused on facility maintenance. It seems everyone is rightly concerned with improving maintainability of their systems.

Service Manager Pete Thompson takes us through some factors that will greatly impact the ease and speed your systems can be restored to operational status after failure. These include: having drawings on-hand, standardised PLC programming, staff skills and attitude, standardised parts and equipment spares, and moving from a reactive to a planned (or better, preventative) maintenance regime.

Read the full article here: Manufacturing maintenance tips: 5 Factors that affect maintainability

Conclusion

Judging by the variation in topics of these top performing blogs, It's clear that our clients and networks are a varied bunch with different interests, challenges and aspirations. But, in servicing the industrial sectors – from manufacturing, utilities, defence, transport, resources and smart city infrastructure – has shown us that though the context varies, the problem solving technologies and methodologies remain the same.

Everyday we solve different problems for different industries using the same technologies and approach. We outline some of these projects in our blog: 6 cross-industry applications of industrial IoT in practice