The state of Industry 4.0 in Australia

SAGE Automation, Published: November 29, 2018 - Updated: February 15, 2026 (6 min read)

Australia’s peak business group leaders have recently stepped up their encouragement of companies to embrace automation, as statistics show the nation is trailing other advanced economies on the road towards Industry 4.0.

With SAGE Automation at the frontier of helping clients to invest in digitisation, we thought a timely update on the state of Industry 4.0 in Australia was due. Here’s a snapshot.

Industry 4.0 is “ubiquitous and unstoppable”

Business Council of Australia chief executive Jennifer Westacott told the National Press Club on October 30 that our lagging business investment in technology is a “red flag” to motivate businesses to examine their processes.

"When I hear people saying they want to slow down this rate of change, erect barriers to transition, and bring back protectionism, I shake my head,’’ Jennifer says.

“This is ubiquitous. It's unstoppable. It's borderless. It's consumer driven. It's skills-focused. If done well, it will be a force for good.’’

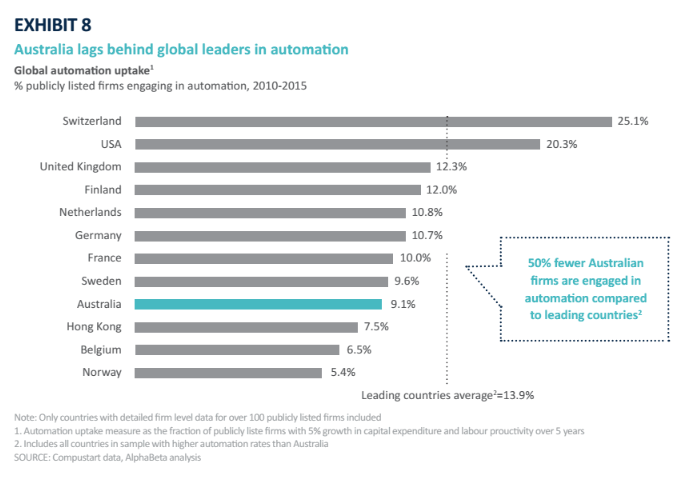

She points to an AlphaBeta study showing only nine per cent of ASX-listed companies are making a sustained investment in automation compared with 14 per cent of global peers and 30 per cent US companies.

Australia lags behind global leaders in automation. Image: Alphabeta report

Australia lags behind global leaders in automation. Image: Alphabeta report

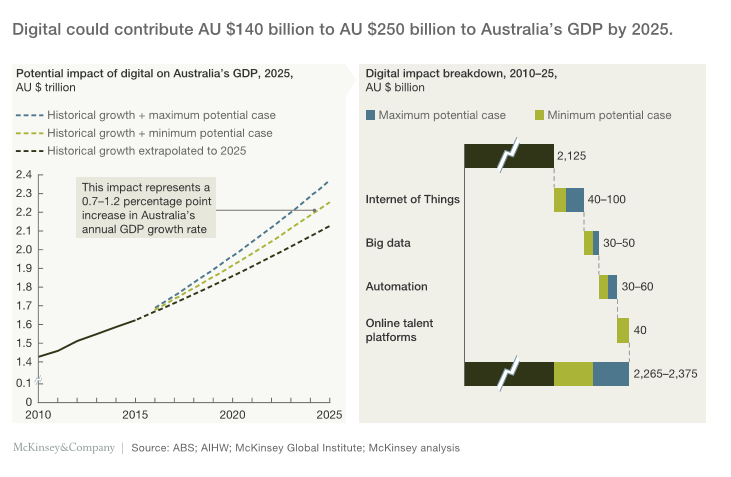

Contrary to CEDA research, Jennifer believes automation will be a positive for Australian jobs, adding up to $250 billion to the Australian economy by 2025:

Image: Mckinsey

Image: Mckinsey

She says job losses to automation are no higher today than in previous peaks of industrial progress over the past 50 years.

Australian manufacturing not just surviving, but thriving

Innes Willox, chief executive of manufacturer peak body Ai Group is on the same wavelength.He says Australia has shown it can be a global competitor, innovator and maker of sophisticated products.

Ai Group’s Performance of Manufacturing Index shows a 25-month expansion, the longest run since 2005, with the sector accounting for 30.4 per cent of all new jobs created in Australia in the year to August 2018.

“We can have a manufacturing sector that does not just survive, but thrives by transforming itself and taking advantage of the possibilities of new technology,’’ he told a recent Siemen Digitize Conference in Melbourne.

“This is not just a pathway for a handful of self-consciously high-tech businesses. It is a road of digitalization, business model innovation and high performance that can manufacturing business can take to become more advanced.’’

Innes says advancing towards Industry 4.0 means having the ambition to grow, learn and innovate at every level and the ability to collaborate with researchers, governments, institutions and workers.

Investment needs to spread from big companies

While Australian business lags behind international peers, Reserve Bank of Australia Governor Philip Lowe is confident investment in technology will spread from leading companies to most businesses over time to boost aggregate productivity and incomes.

He says progress so far on software and information technology investment has come from the top end of town.

“Advances in information technology, in artificial intelligence and in machine learning have the potential to reshape our economies profoundly and lift average living standards in ways that are difficult to envisage today,’’ Dr Lowe says.

SAGE clients closer to Industry 4.0

SAGE Automation’s own data shows its clients are leaders in Australian industry investment in digital technology solutions.

Revenue from SAGE’s digital solutions business Nukon has increased by more than 566% since 2013.

In 2017, demand for digital solutions was strong for food and beverage, manufacturing, water, and increasingly, infrastructure, where connected intelligent transport system (C-ITS) technologies are helping manage road congestion and open the door to a driverless car future.

“Industry 4.0 is affecting every industry,” SAGE Group CEO Adrian Fahey says. “Our utilities clients are investing and benefiting from the same technologies as those in civil construction or transportation.”

“It shows just how pervasive digital technologies and the Internet of Things (IoT) can be. The ability to connect, monitor and control things remotely is giving Australian businesses a better, smarter way to manage their assets, and ultimately gain competitive advantage,” he says.

SAGE’s clients are investing in anything from new manufacturing and business system software, data integration and analytics, remote site monitoring and communications, integrated data platforms, machine sensors, and cloud solutions like SAGE’s cloud-based SCADA service ‘STRATUS’.

Major companies around the country are aware of the opportunity around ‘digitisation’ and technological improvements. We’re seeing more and more job titles for ‘digital improvement lead’ or ‘industry 4.0 lead’ on LinkedIn - and this just reflects the way the industrial sector is headed.

If you’d like to keep up to date with how Australia's industrial industries are advancing, sign up to our monthly newsletter.