SAGE Group has officially expanded its manufacturing footprint with the commissioning of the new Advanced Manufacturing Centre, an investment that significantly enhances production capacity and operational agility.

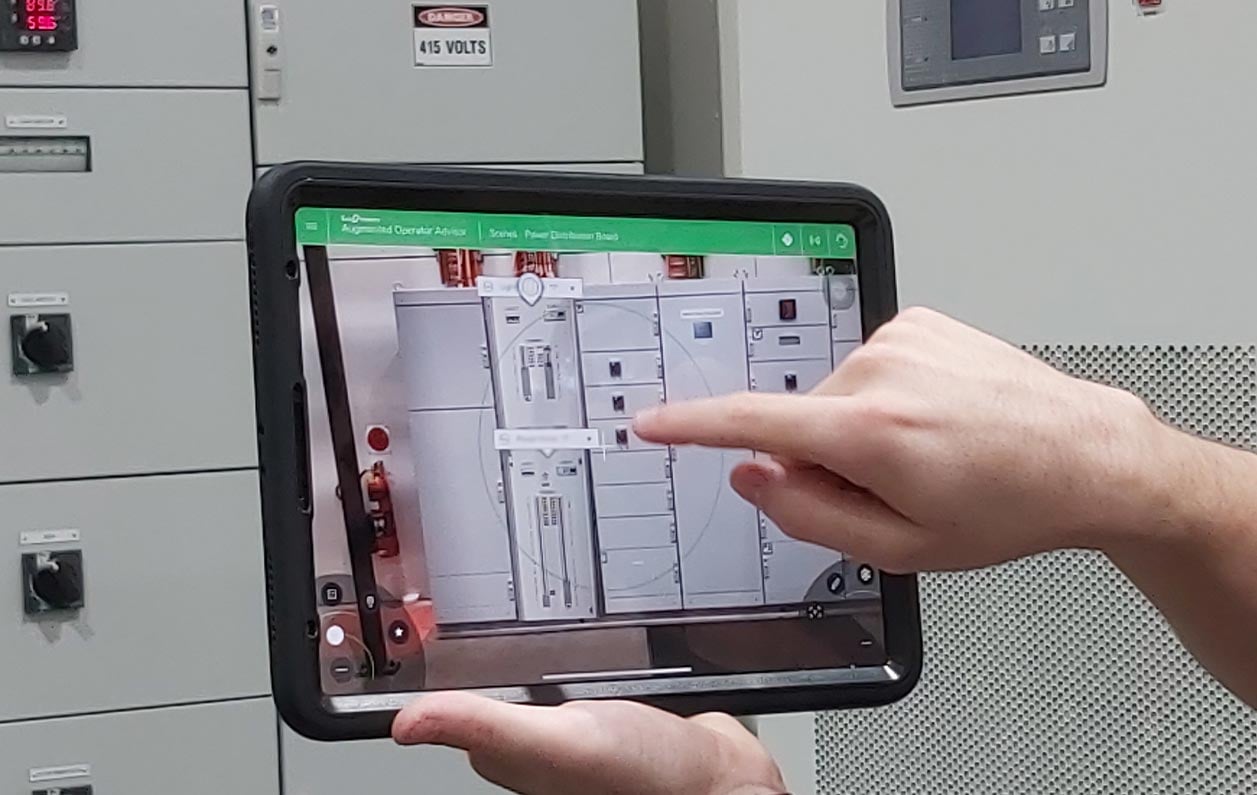

SAGE Automation has added augmented reality (AR) to its maintenance ability, recently deploying Schneider Electric’s EcoStruxure Augmented Operator Advisor platform. Using image recognition, the software allows a technician to inspect and diagnose through an app, which superimposes real-time data and virtual objects onto electrical cabinets, machines, or other assets within the plant.

SAGE Automation has acquired Geelong-based System Integrator, Industrial Control Technology (ICT), to expand its geographic footprint in Victoria.

A group of more than twenty representatives from Destroyer Enterprise, including Thales Australia Engineers and Royal Australian Navy personnel from NUSHIP Sydney, were impressed by SAGE Group's Industry 4.0 training and manufacturing capabilities during a tour of the company's headquarters at Tonsley.

The Premier Integrator status with Inductive Automation highlights the depth of experience within the SAGE team.

The Komax Zeta 640 cabling machine is the latest piece of SAGE’s Industry 4.0 transformational journey, enabling SAGE to ramp up its manufacturing capability more than ever before.

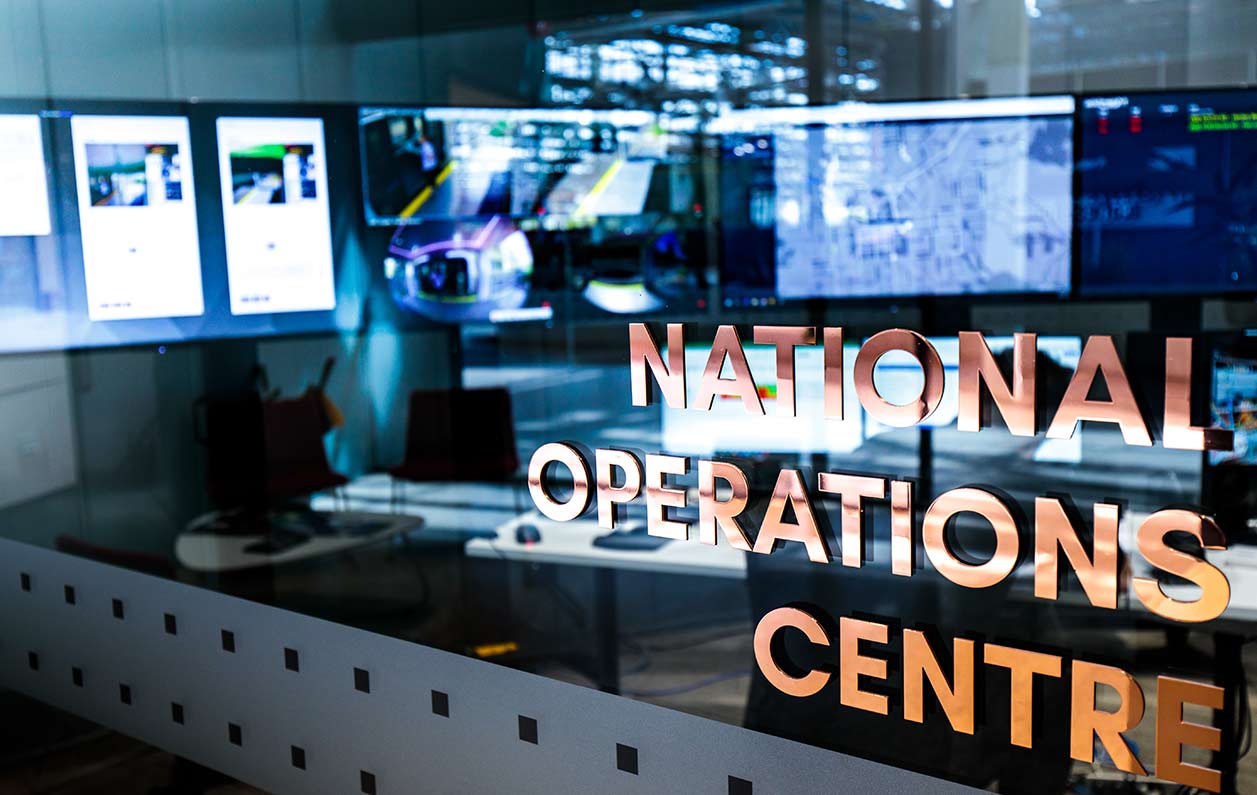

SAGE clients can expect to pay less for their control system fault resolution, and bounce back from downtime faster, when they opt to use SAGE Automation’s newly launched National Operations Centre (NOC) for remote support.

SAGE Automation has partnered with University of Adelaide engineering students to implement a series of industry 4.0 improvements set to revolutionise its manufacturing process.

Existing SAGE Automation clients and broader industry alike are set to benefit from the company’s newly optimised manufacturing facility at the Tonsley Innovation Precinct.