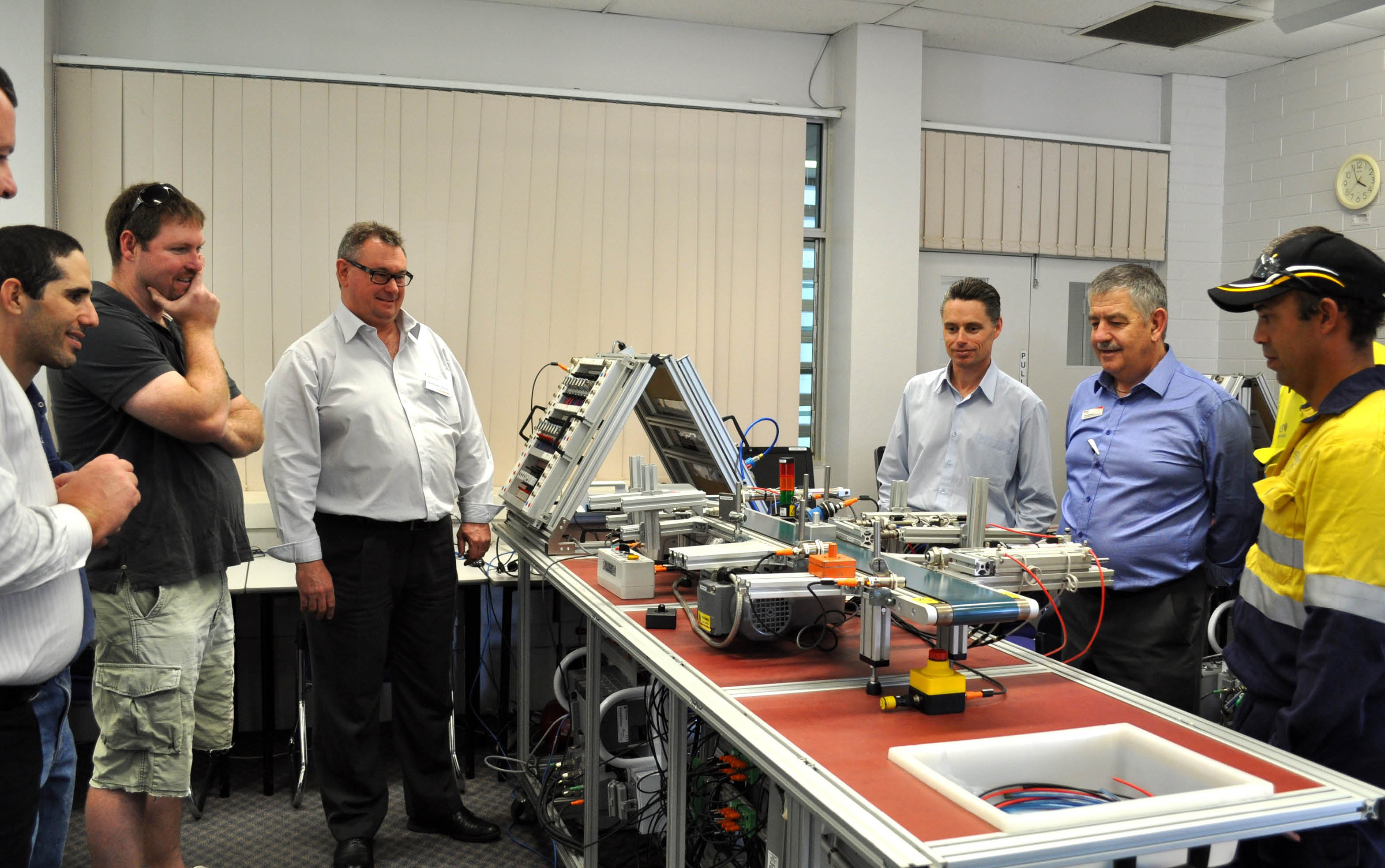

Targeted, practical instrumentation training filled a major skills gap in the Mt Isa mining sector.

SAGE engineering ensures an underground mining explosives system is flexible, rugged and safe.

SAGE supported Metso’s railcar dumper system with tailored PLC and SCADA packages and ongoing service…

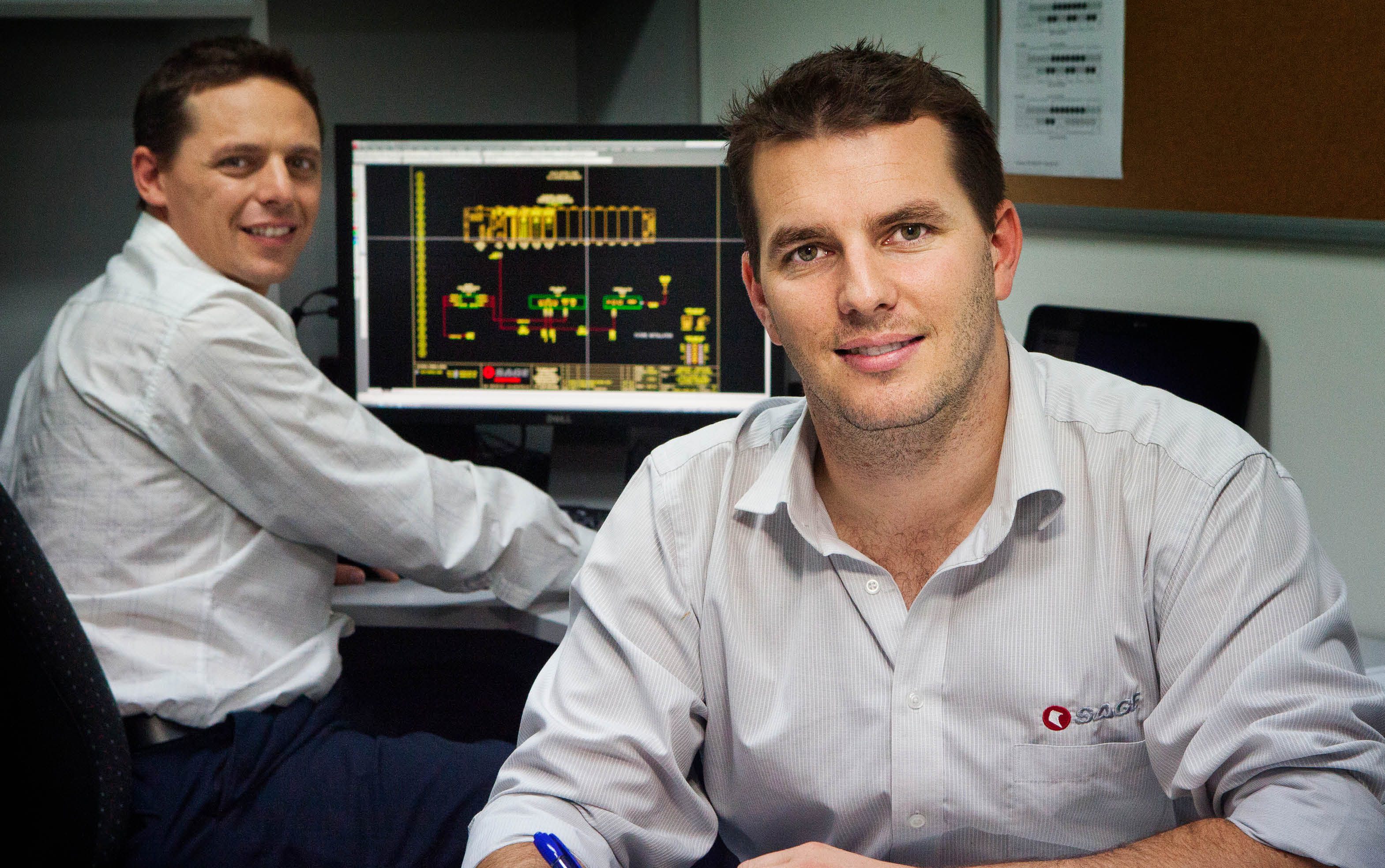

This partnership ensured Boart Longyear had the best control systems for its drill rig manufacture...

SAGE provides a future-proof control system for the new crushing and screening plant including...

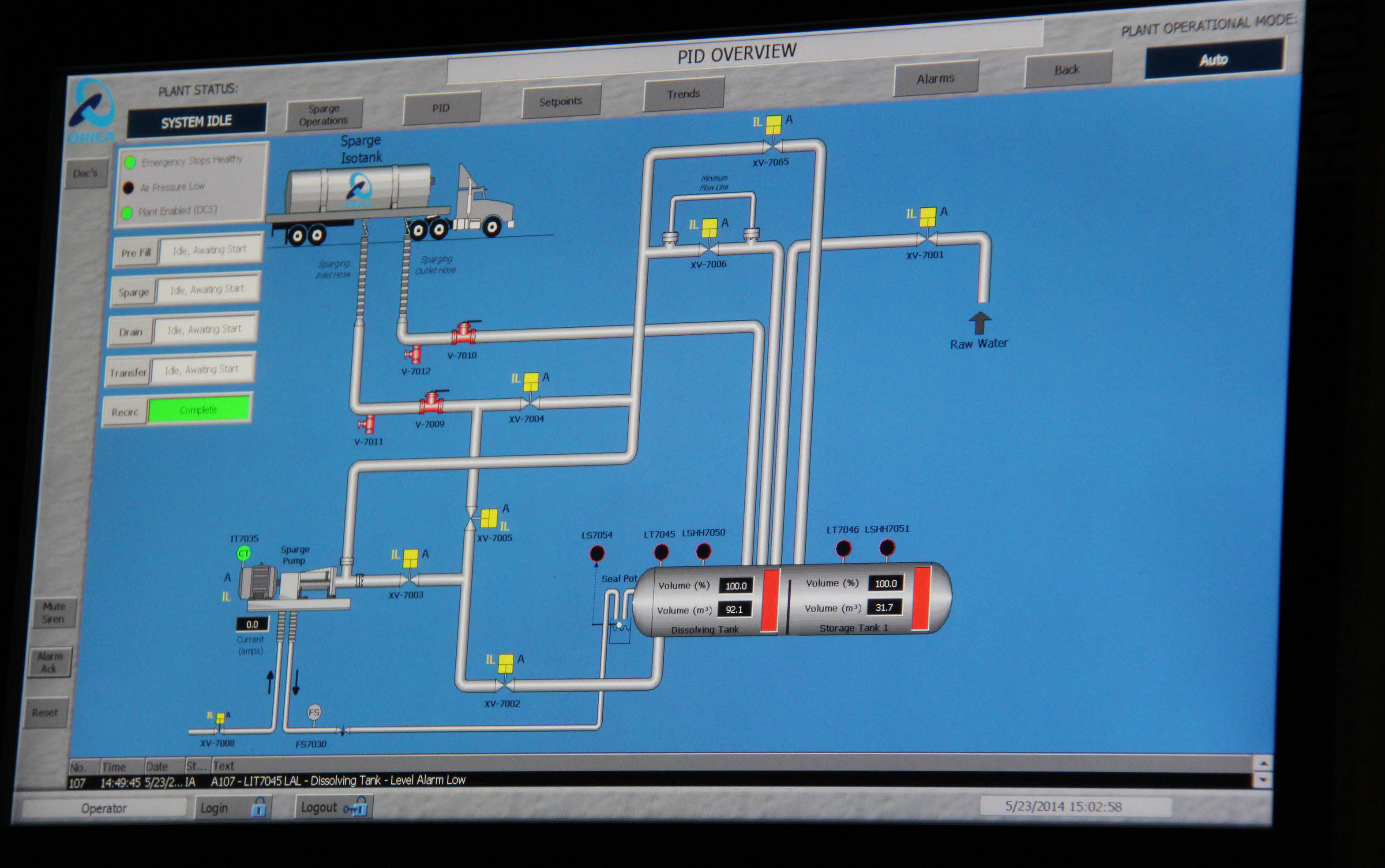

SAGE Automation designed and built the control system for safe cyanide handling – a necessary chemical for extracting…