SAGE delivered the ITS for the T2T managed motorway under the T2T Alliance. SAGE first and foremost focused on safety in design and maintenance, delivering a number of innovations that ensured it was operatable and maintainable.

ITS components integrated and installed:

- 56 Lane Use Management System (LUMS) signs

- 6 full colour, pictogram Variable Message Signs (VMS)

- 39 x CCTV cameras

- 72 x Thermal Image Detection System (TIDS) cameras with 100% lowered motorway coverage

- 98 in pavement vehicle detection loops

- 4 pairs Infra-Red Traffic Loggers (IRTL)

- 12 Addinsight Bluetooth detection devices

- 23 custom, double skinned ITS cabinets with UPS back-up to all devices

- 4 large VMS cantilever gantry structures

- 7 x traffic signal extension enclosures

- 126 x custom built device enclosures

Cable Installation Terminates & Testing including:

- 71.3km of cabling for redundant network, power supply, and ITS devices.

Highlights

1. Safety in Design

All devices are extra-low voltage (except VMS and LUMS), and the equipment controllers are accessible via the grade level road versus the lowered motorway. This ensures maintenance can occur without closing road or lanes, and the safety of maintenance personnel.

2. Future-proofed corridor

The managed motorway was built with spare network connectivity so that 95% of the fibre cores are available to use for rapid future technology deployment such as autonomous vehicles.

3. Uninterrupted Power Supply (UPS)

A minimum 4-hour battery backup in all field systems ensures the entire ITS network operates in a network or power failure. Other systems to-date have battery backup in VMS only, which means the system still goes down.

4. First motorway with 100% video incident detection

The thermal Video Incident Detection System detects slowing, stopped or wrong direction vehicles within 5-15 seconds. This fast-tracks incident response actions like notifying drivers of lane closures via the Lane Use Management System signs, reducing incident-related congestion and the stress it can cause.

5. Australian control panel manufacture

The SAGE developed all 23 custom, double skinned ITS cabinets’ electrical schematics, then manufactured them at SAGE’s Advanced Manufacturing facility in Adelaide.

6. Addinsight enabled

The motorway is equipped with bidirectional Addinsight Bluetooth capture stations which provide real-time traffic volume data for both the lower managed motorway and top roads.

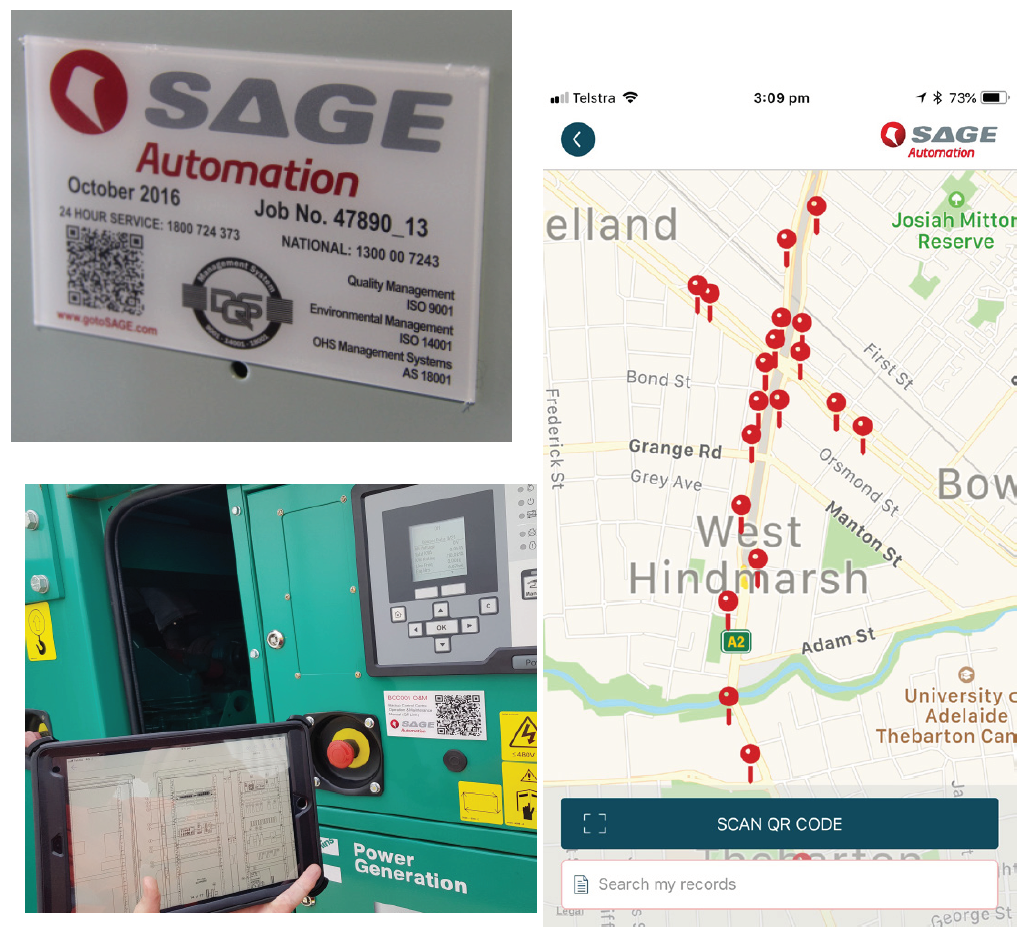

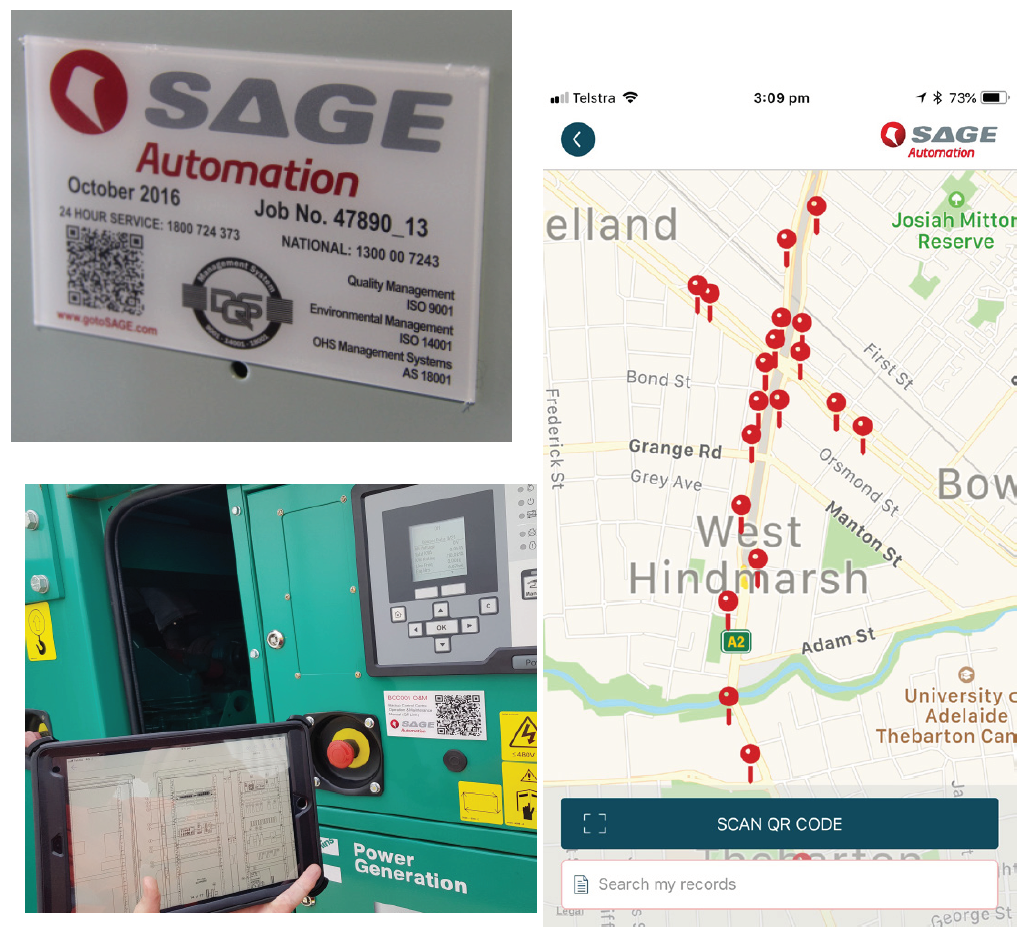

7. Industry-first paperless commissioning and maintenance records

All commissioning was completed digitally, saving hundreds of reams of paper, and speeding up the process by reducing double handling.

In addition, SAGE provided digital equipment documentation for all ITS devices, accessible on-location via barcode and mobile phone - an industry first of its kind.

The paperless documentation system was transferred to the SAGE Go app at handover, which allows users to access all documentation, view cabinets by location, and lodge a breakdown or maintenance request.

8. Innovative Factory Acceptance Testing (FAT)

Comprehensive FAT of devices prior to field installation significantly reduced risk, sped up delivery and minimised traffic disruption by proving the whole system prior to deployment.

This approach has advanced best practice, and is used for other SAGE projects including Monash Freeway and Darlington.

Unique delivery partner

Alliance partnership

SAGE enjoyed working under the alliance delivery model, which was hugely successful due to its collaborative, best for project approach.

Australian Industry Participation

SAGE remains committed to exceeding industry participation for all its projects. SAGE employed and developed two young indigenous Australians in apprenticeships, and numerous graduate and work experience engineers who worked on the T2T project until final commissioning.

Integrated training

In a commitment to safety in design and maintainability of the system for the end user, SAGE ensured all DPTI personnel were trained prior to commissioning. SAGE’s training business Skills Lab, engaged DPTI early to tailor the operations and maintenance training.

Safety first at SAGE

The Alliance awarded SAGE an Outstanding Performance award for exemplifying the T2T Alliance core values, particularly in relation to its work around safety.