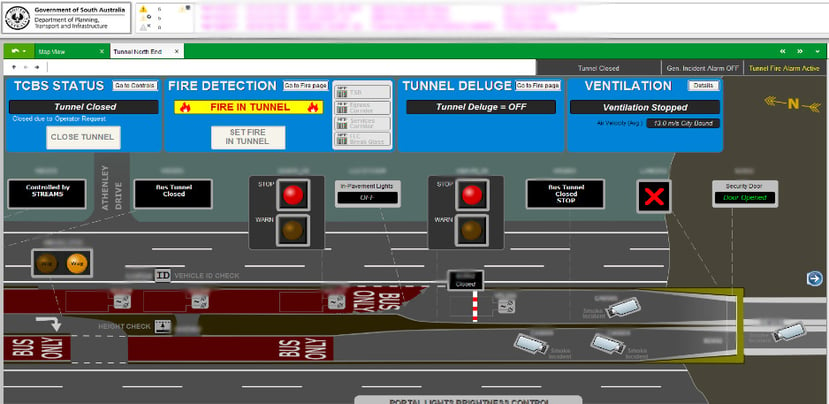

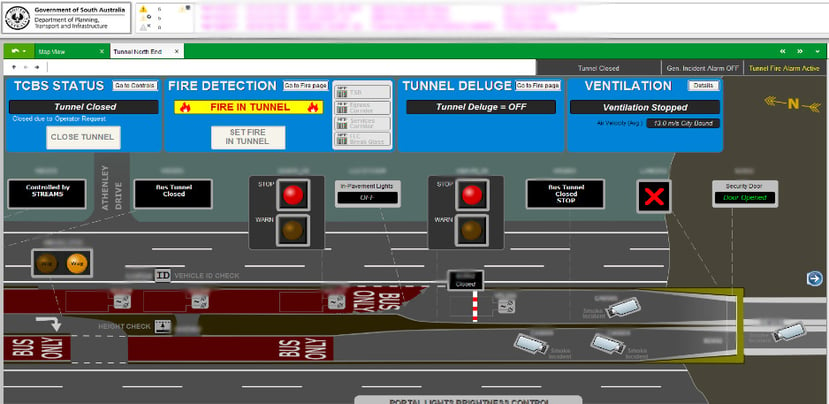

SAGE provided a turnkey solution for the main works contractor McConnell Dowell, ensuring the safe and efficient operation of the new 670-metre O-Bahn tunnel and its approaches. SAGE designed, manufactured, installed and commissioned the systems required for the intelligent transport system (ITS), tunnel control, fire-life safety, ventilation, deluge pumping, and power monitoring systems.

Careful consideration was given to reducing whole-of-life costs for the tunnel, in particular: energy efficiency, life expectancy, routine maintenance requirements and local supportability.

ITS tunnel solutions

-

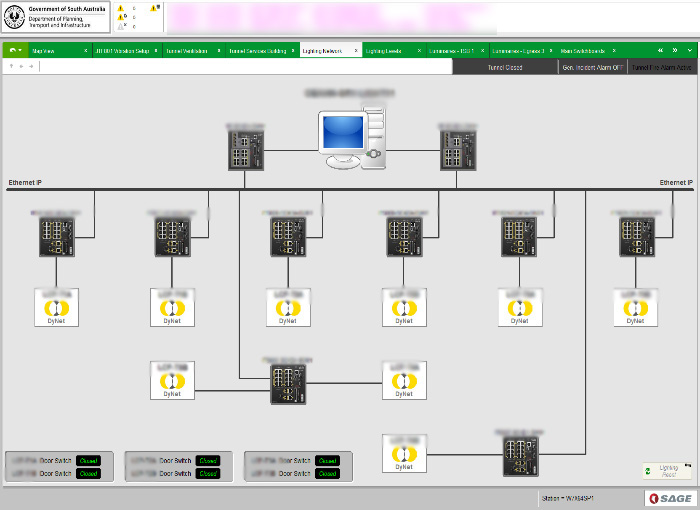

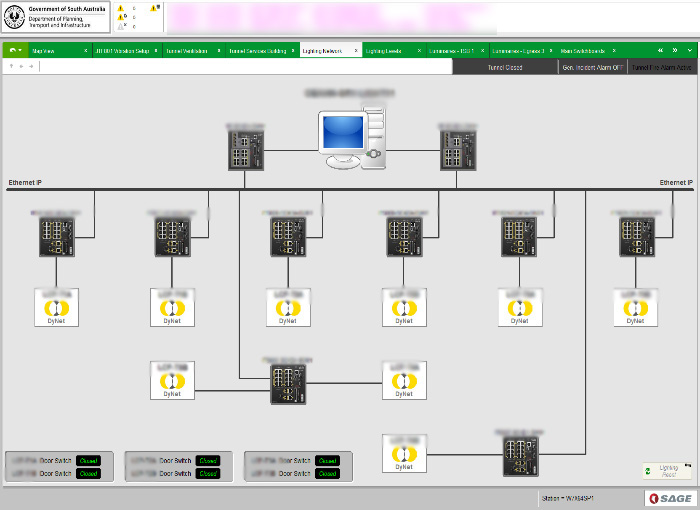

High level communications

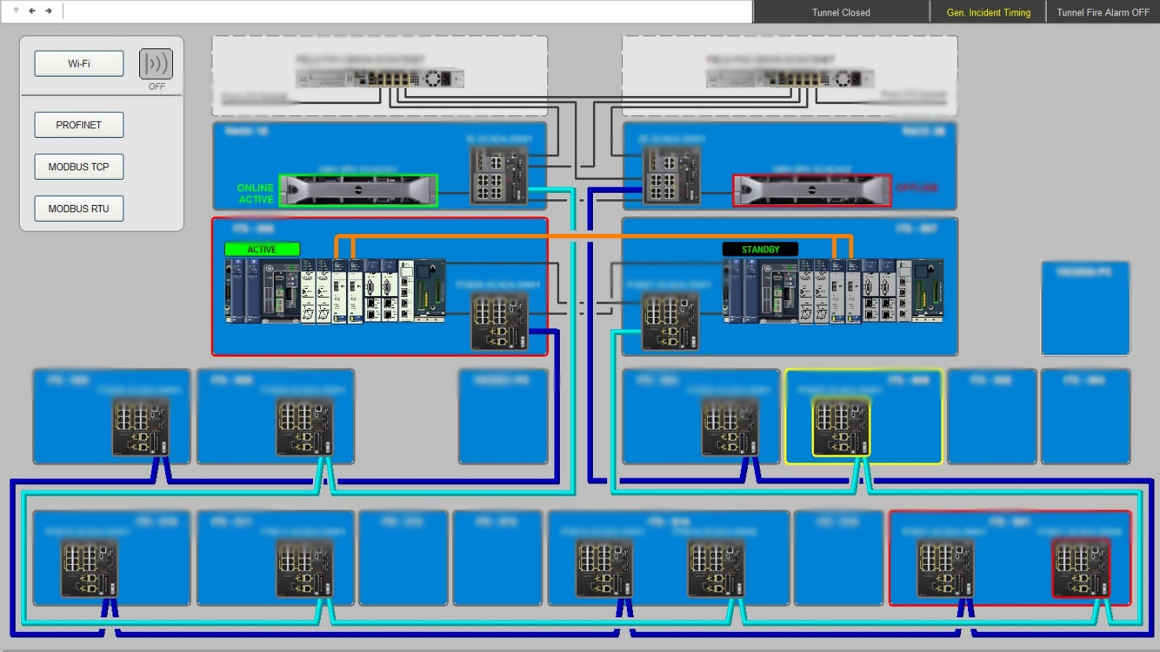

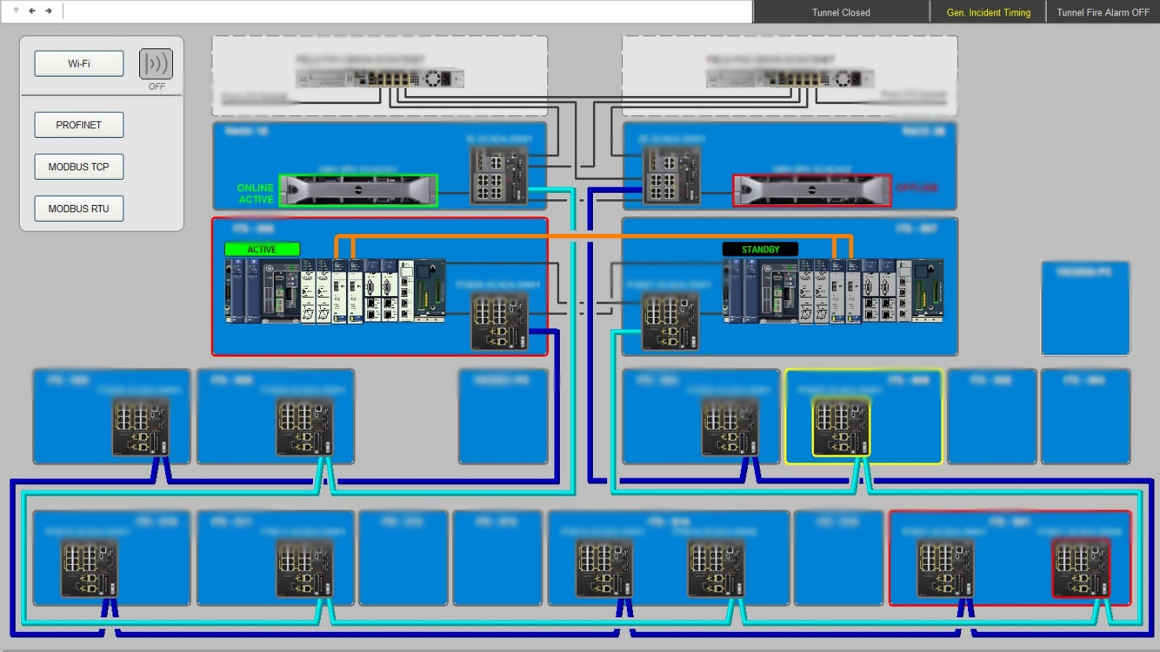

This system provides advanced diagnostics for all tunnel subsystems. A redundant fibre network connects each system, ensuring maintainability and flexibility to scale in the future. This results in less cabling, greater diagnostic ability and reduced construction costs.

-

Redundant networks

The tunnel is equipped with a fully redundant controls system and network that can handle multiple points of failure. The entire system, from the PLC, through to security cameras communicate through a physically separate redundant ring network.

-

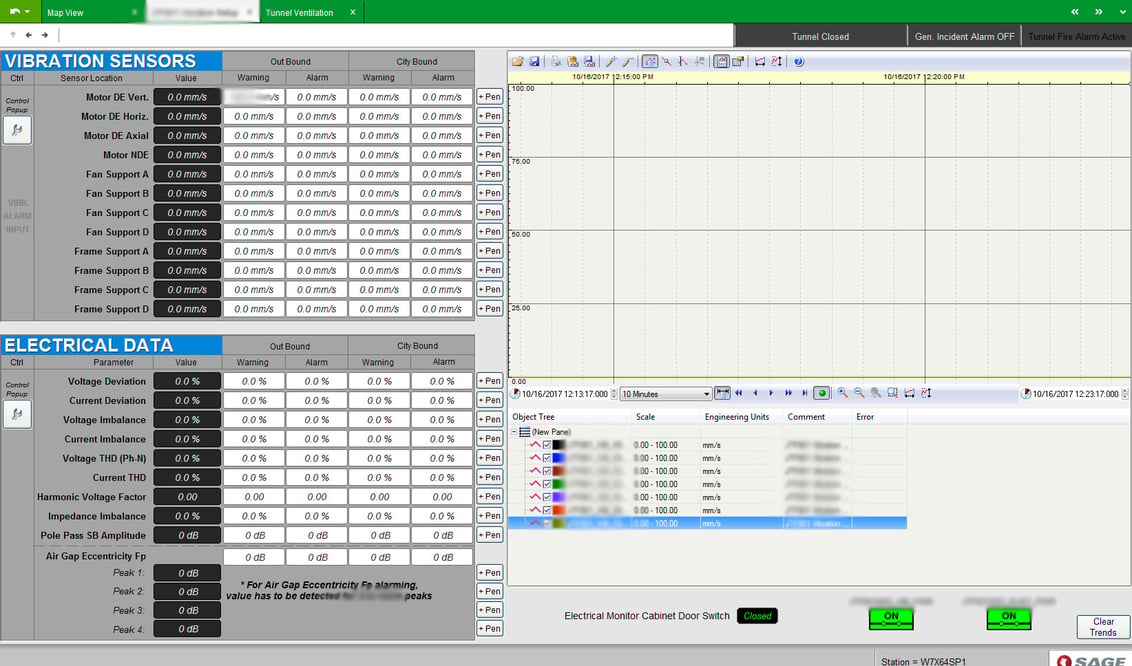

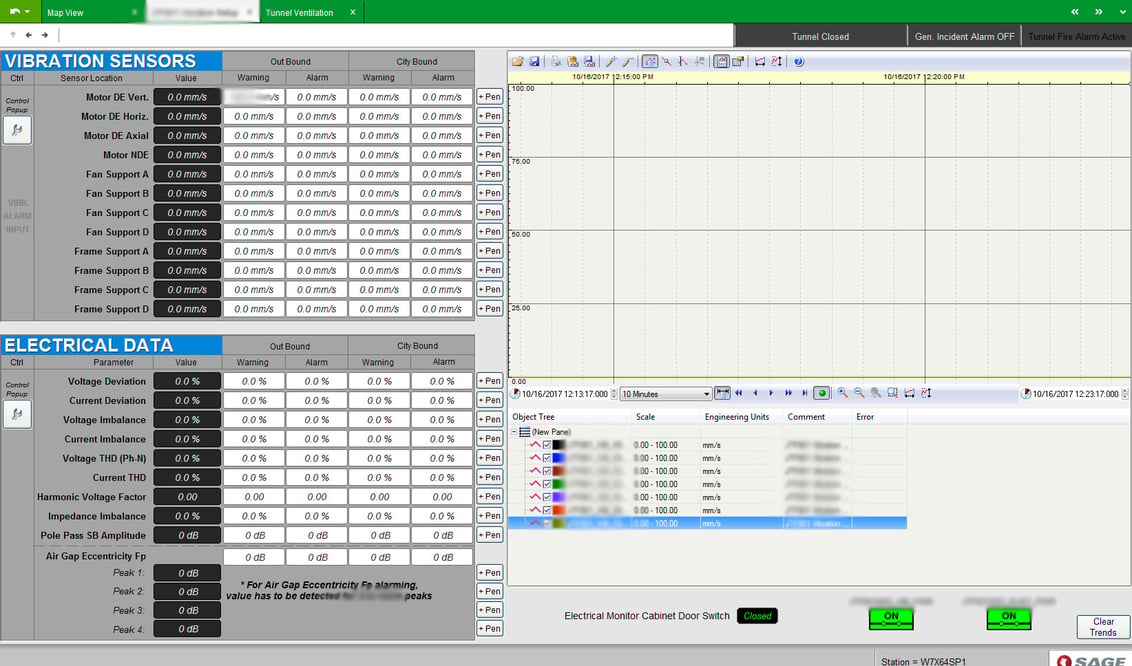

Fan vibration monitoring & electrical monitoring

Vibration and electrical trend data from the tunnel’s ventilation fan blades, motors and mounting brackets detect and report wear and tear before breakdowns. This predictive maintenance capability increases fan lifespan and reduces lifetime maintenance costs while increasing tunnel availability.

-

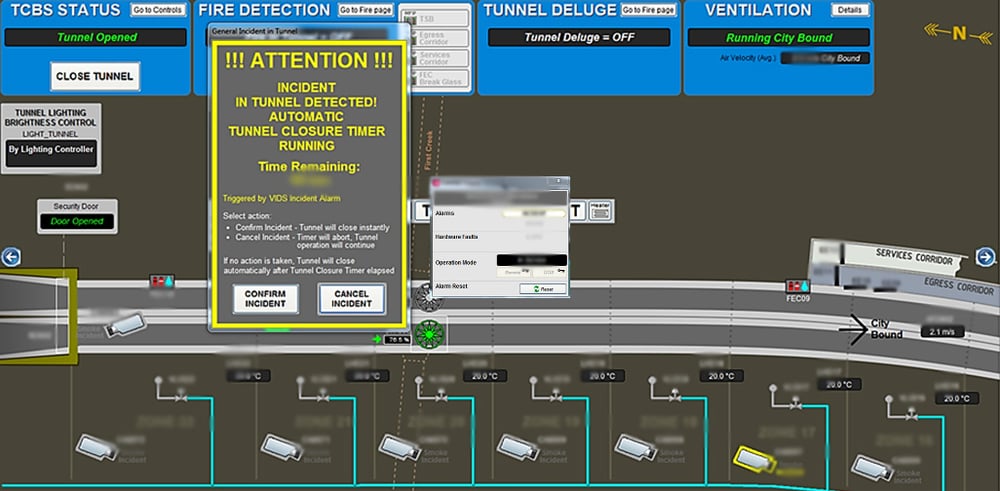

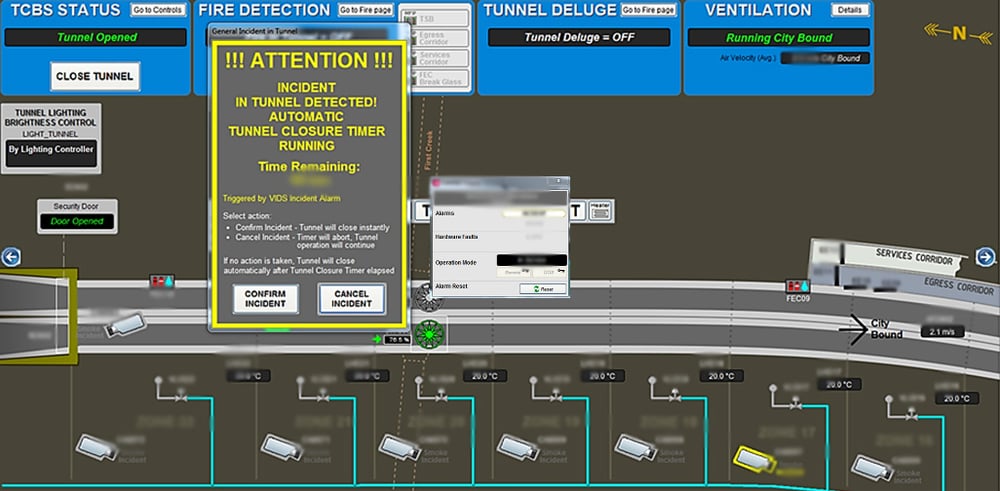

Video incident detection

The tunnel is equipped with automatic incident detection cameras that detect abnormal activity such as smoke, unauthorised persons, wrong traffic direction and stopped vehicle or debris. Incident alarms are sent to the traffic management centre and/or control system for automatic response, allowing for instant situational management. In addition, cameras are positioned to sit underneath the smoke layer in the event of fire.

-

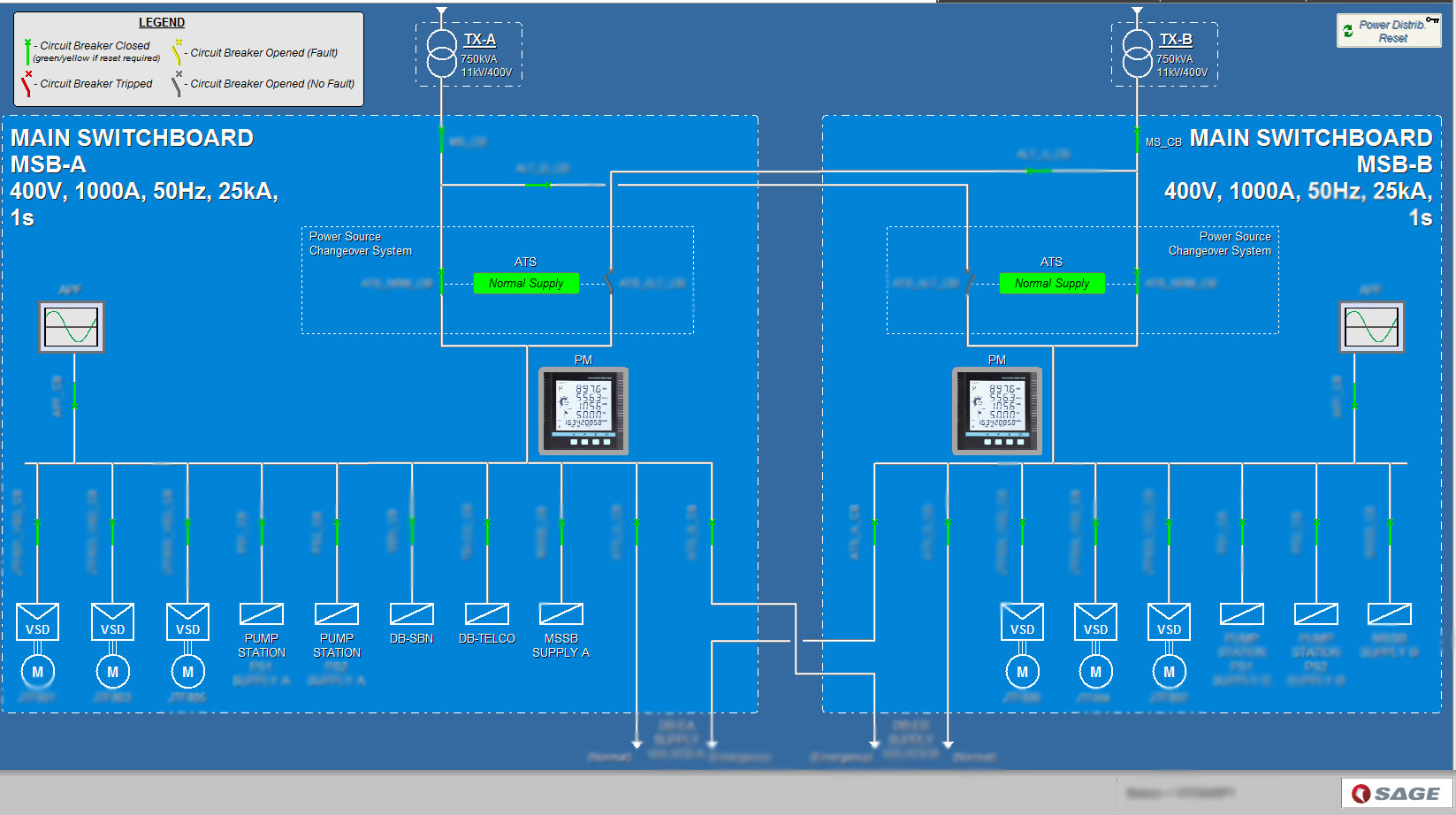

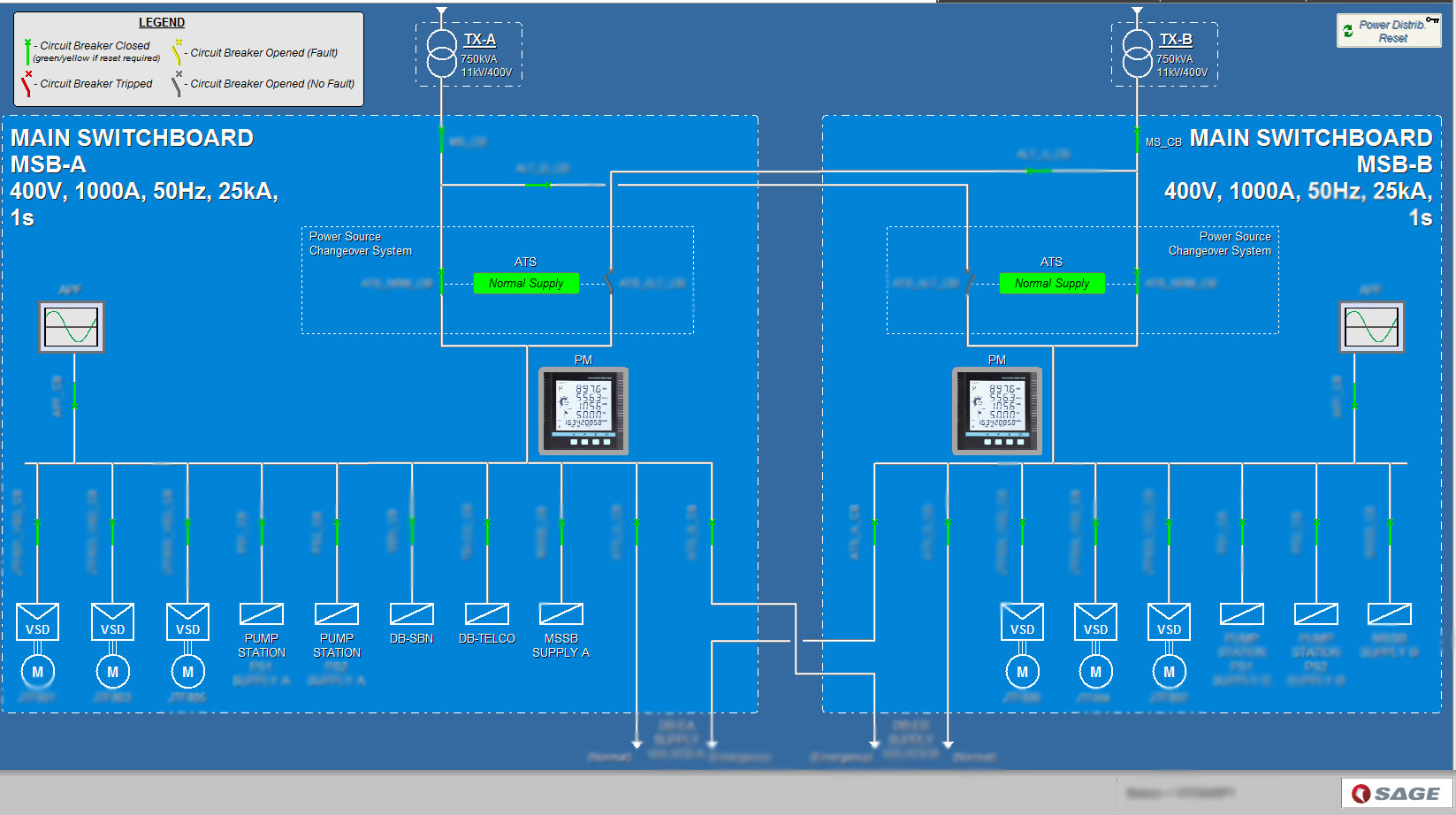

Power management via power distribution & monitoring system

A power factor correction and harmonic controller reduces power costs and increases the life expectancy of devices, while a power monitoring solution provides diagnostics to analyse potential faults before they occur. Full physical redundancies ensure tunnel energy supply.

-

Panel manufacture

SAGE designed, manufactured and tested:

- Main switchboards

- Distribution boards

- ITS control panels

- ITS pole cabinets

- Lighting control panels

- Jet fan vibration monitoring control panel

- Jet fan motor power monitoring control panel

Local design and manufacture of panels at SAGE’s Advanced Manufacturing Facility ensured they were delivered on time to a world standard quality.

-

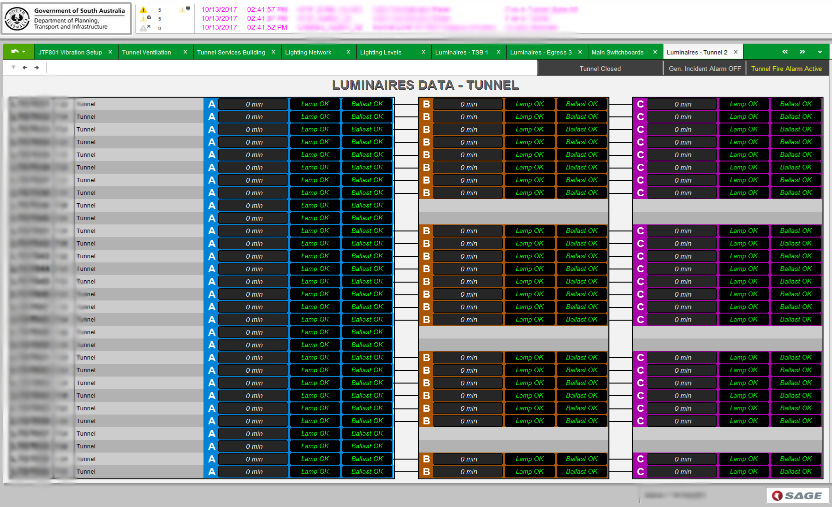

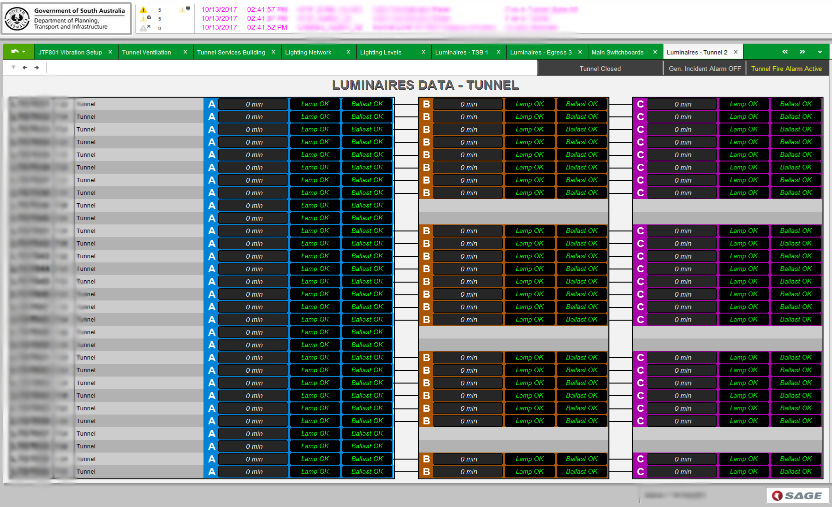

LED lighting control system

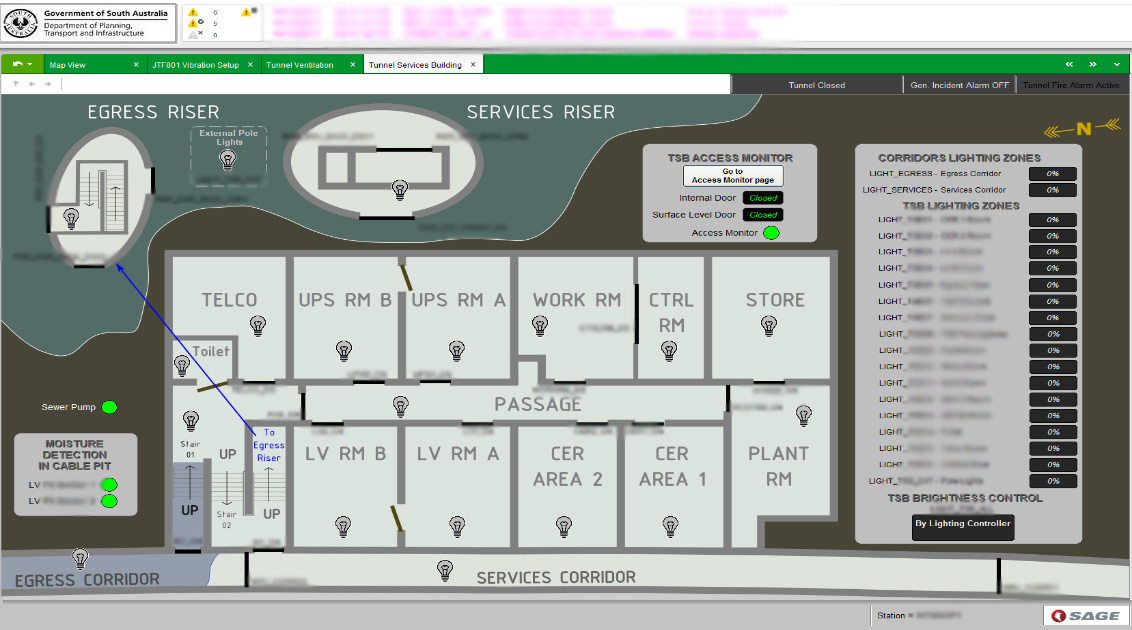

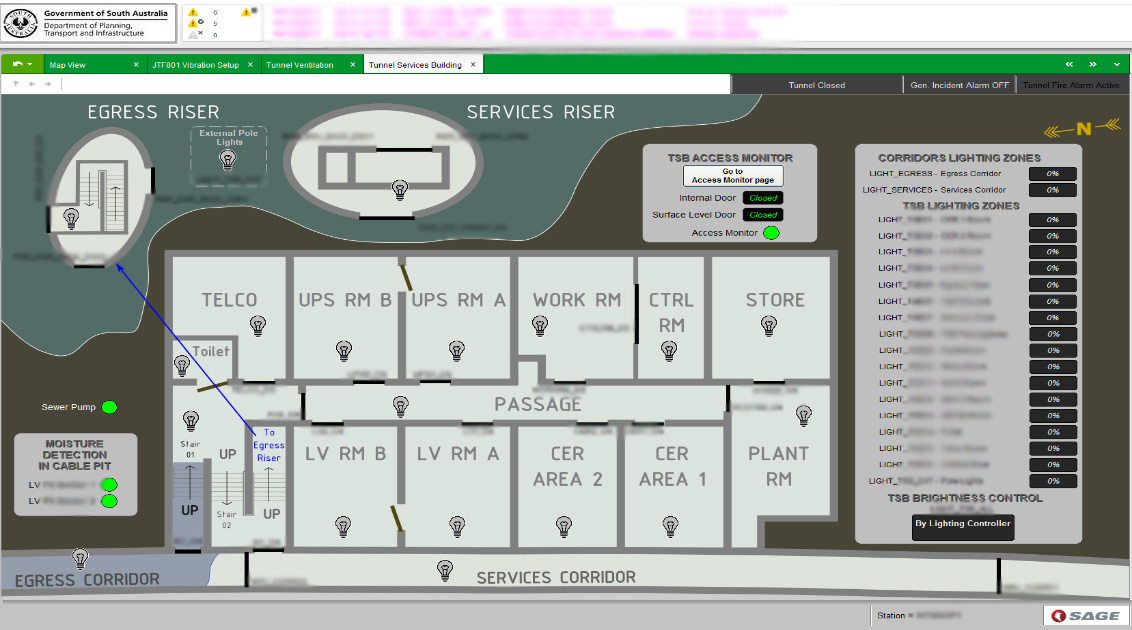

This is the first wholly LED lit tunnel in Australia featuring advanced integrated control and fault management facilities, as well as the first deployment of LED egress guidance lighting system. All this is maintained through a SAGE designed SCADA interface.

Sub-system features

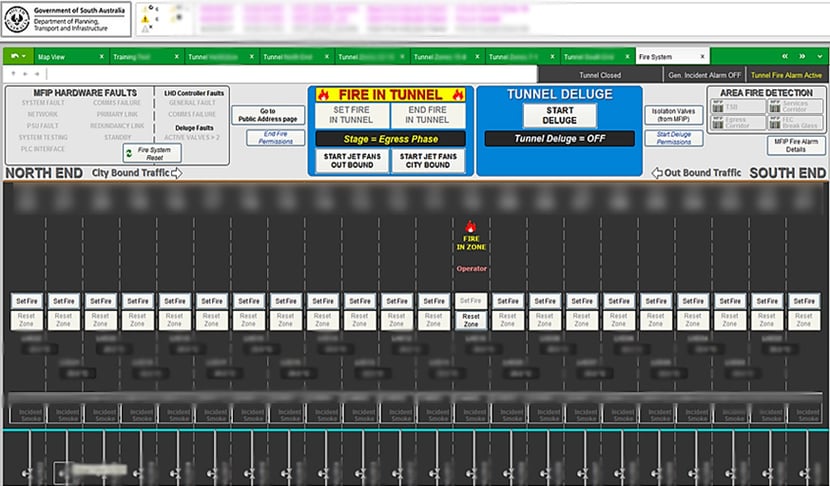

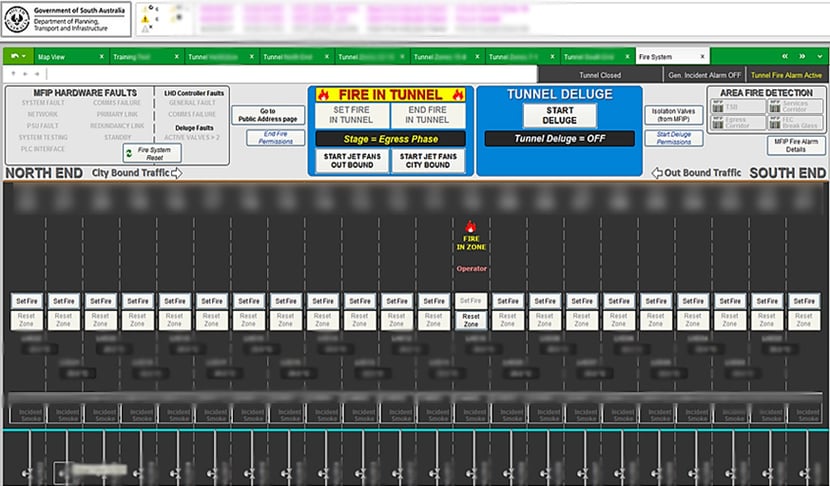

Operations Management Controls System (OMCS) and Plant Management Control System (PMCS)

These systems are equipped with a highly functional SCADA interface, giving operators unparalleled controls and visibility of all tunnel subsystems through one interface.

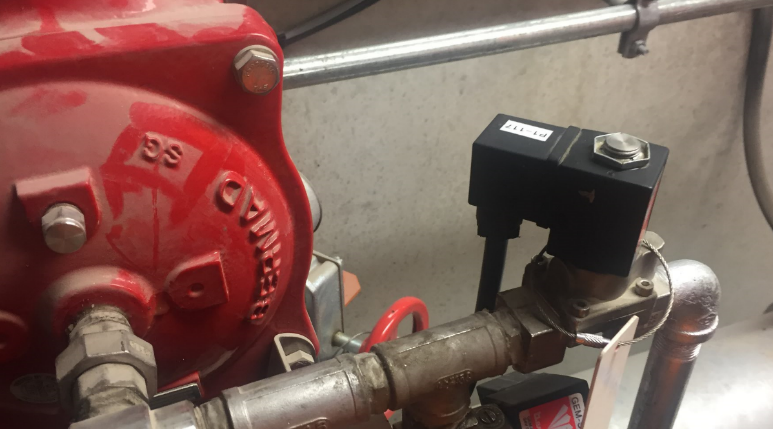

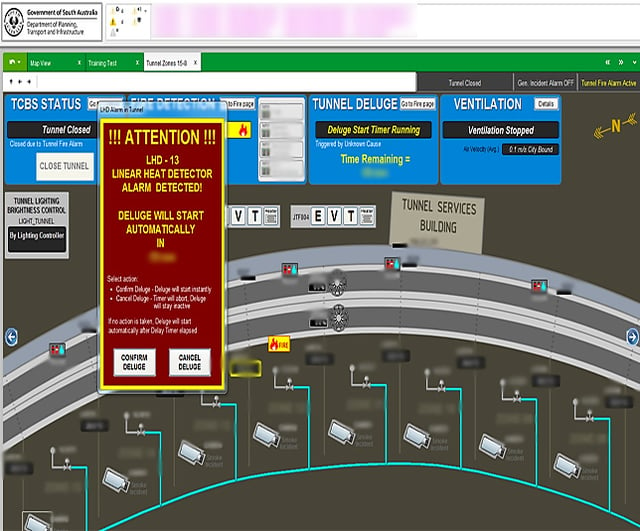

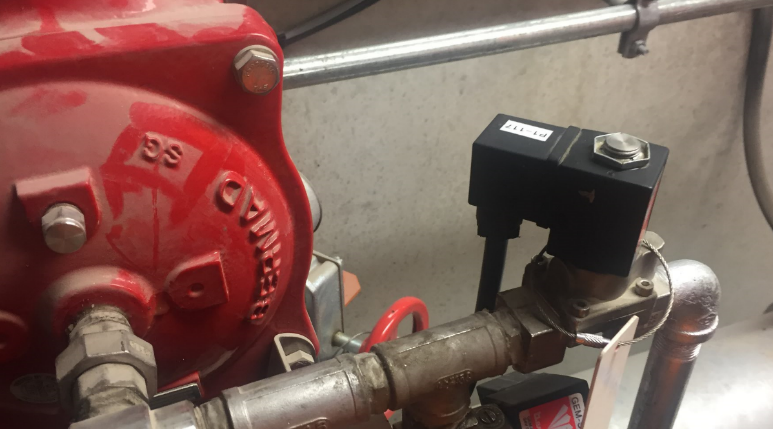

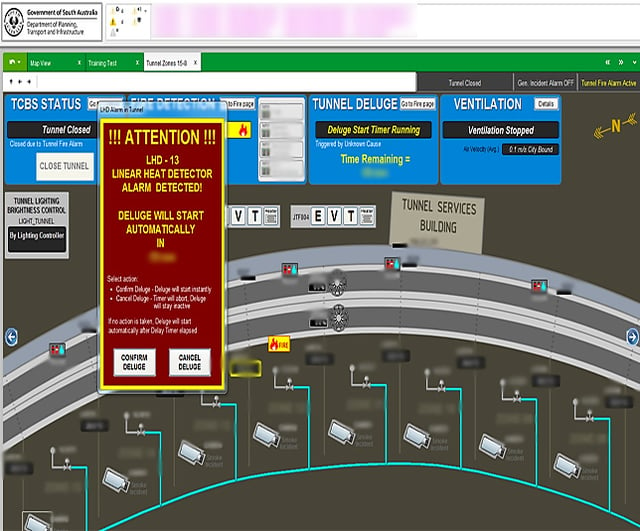

Fire and deluge system

The SCADA interface is fully integrated with the independent fire detection system, giving operators a real-time visual representation of fire events within the tunnel. This allows operators to brief firefighters early, and activate remote firefighting protocols via the deluge system.

Linear heat detection

As part of the fire detection system, linear heat detectors sense the temperature along the tunnel, giving operators the fire location with pinpoint accuracy. This information can be passed to firefighting services to allow for a faster, more effective response.

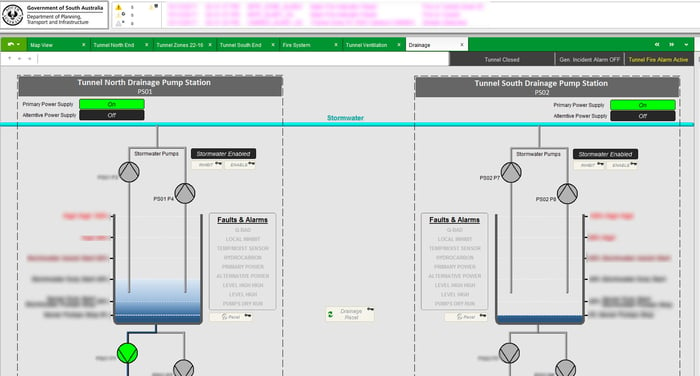

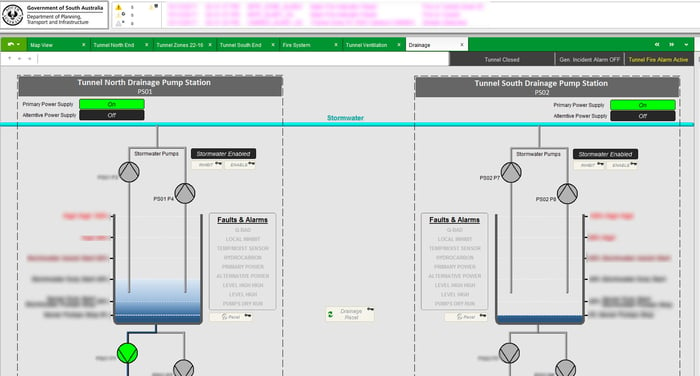

Tunnel drainage

Two redundant sumps collect and drain water under the tunnel and are equipped with a fully redundant control system that detects and alarms for hydrocarbon levels, temperature, water levels, power, and moisture. Automatic actions allow water to be either pumped to stormwater drainage or the sewer system, based on water quality.

Public address system

Tunnels speakers have been acoustically designed for the shape and construction materials of the tunnel so the sound is not distorted. This ensures all messages, whether recorded or live are understood by those within the tunnel. An audible and intelligible speaker system is a highly important safety aspect in the event of fires or major tunnel event.