Our customer engaged SAGE Automation to assist with the electrical controls and automation of a new MRF and glass plant in a purpose-built facility.

The solution involves the recyclable waste travelling along conveyor lines and being sorted into like materials using optical sorters. The sorters use air pressure to separate paper from cardboard and cans from bottles, these items are then transferred into a designated bin. The operators can use the system HMI to select sorted materials from the bin to be compressed and baled with the same materials – a requirement for international export.

Glass is collected along a separate line and crushed for recycling.

SAGE provided the control systems for the auxiliary equipment in the factory. This includes important elements such as controlling the speed of the conveyor the recyclables travel on, the optical sorter, as well as the emptying of bins into the baler. The design uses PLCs, HMI, VSDs and FTView SCADA which form part of the controls for the main recyclables and the glass line plant Motor Control Centres (MCCs).

SAGE developed PLC and HMI software to ensure quality of system functionality and data aspects of the project. This includes implementing tablet devices with the HMI, enabling operators to view and control the plant from any location within the facility.

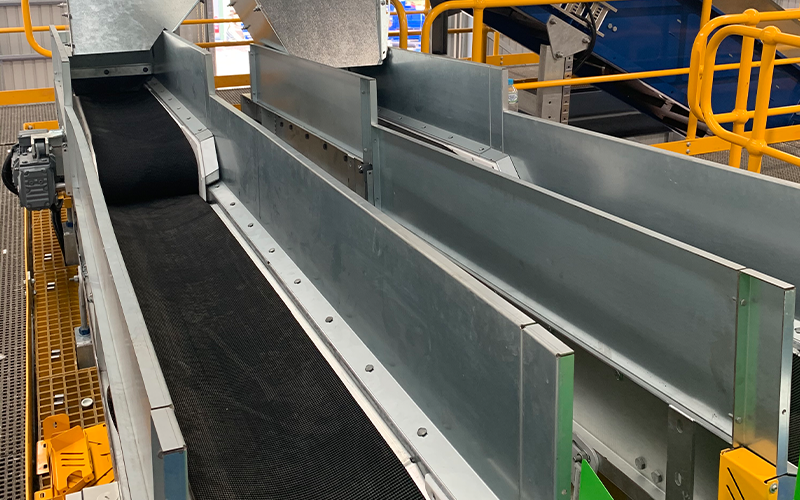

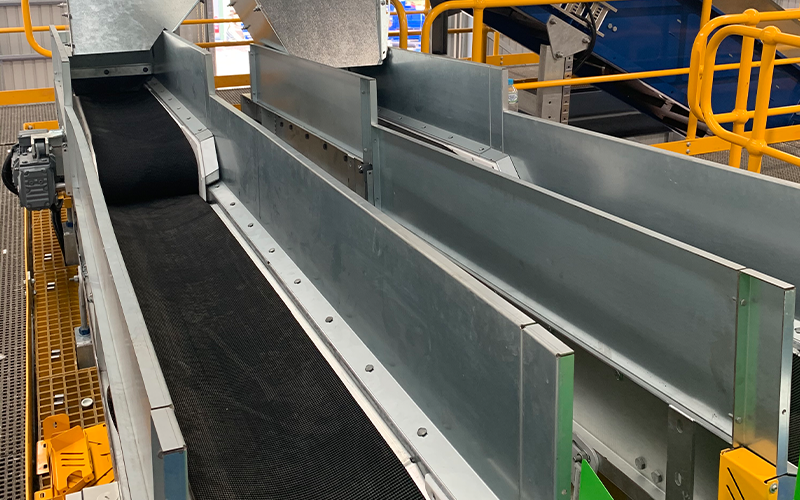

The conveyor system

SAGE delivered controls for the conveyors and additional sorting equipment that is used to transport the recyclables around the MRF. From their initial delivery point the products are sent along a conveyor system to the optical sorters. Once the items are sorted into like materials they are then transported to bins where they are stored until they are baled.

The optical sorter

Optical sorters use camera technology to differentiate between different product material on the conveyor. Once the material has been identified, the optical sorter uses air pressure to blow items down the correct chute and into the designated collection bin. SAGE ensured the successful integration of Machinex optical sorters within the system.