Fulton Hogan engaged SAGE Automation to build a transportable, smarter, and safer system for heating bitumen in remote locations. SAGE, in collaboration with our partners Cornell Design and Specialised Solutions, delivered two built-for-purpose 20-ft bitumen heating containers with an innovative electrical control system.

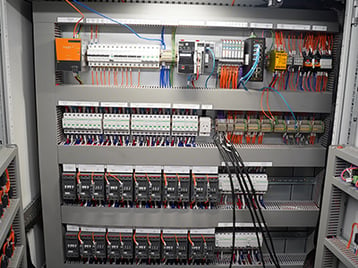

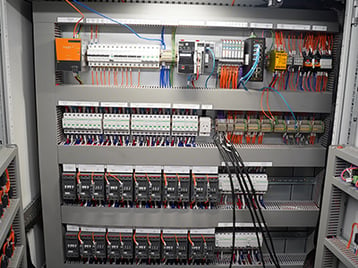

SAGE engineered two high-power LV switchboards capable of heating bitumen within each container with varying heating requirements. Advanced PLC programming was a requirement in delivering a smart control system that allows operators to utilise anything from an automated slow heat cycle to a high heating cycle, and anything in between, based on their current requirements. Each system can heat two bitumen containers at once, providing Fulton Hogan with the capability of heating up to four bitumen containers utilising proportional enhanced electrical control.

The two LV switchboards were manufactured in SAGE’s Manufacturing Facility in Tonsley, South Australia, and installed into two shipping containers featuring 64, 10KW heating elements. Each of the LV switchboards features a touch screen Human-Machine Interface (HMI) for ease of use for operators. Additionally, a 4G modem was installed to allow remote access.

SAGE engaged mechanical design partner, Cornell Design for the unique layout design of two 20-ft shipping containers, which, when modified, would become the new bitumen containers. The design per container was required to accommodate one SAGE-built LV switchboard, 32, 10KW heating elements, 32, 7.5m long cables, one 4G modem, along with an air-conditioned break room for staff in each container.

Additionally, SAGE introduced mechanical manufacture partner, Specialised Solutions for the mechanical manufacture required for the two 20-ft bitumen containers, tailored to the approved design developed by Cornell Design. SAGE partnered with these two high-quality industry specialists to deliver the best end-to-end solution for the client while providing a single point of contact.

Prior to the solution being dispatched to Fulton Hogan for use, Factory Acceptance Testing (FAT) was conducted by SAGE and witnessed by the client on-site.