SAGE PIDA finalists for War on Waste recycling solution

Published: April 19, 2018 - Updated: April 23, 2018

SAGE Automation and Container Deposit Systems (CDS) have been announced as finalists in two categories of the 2018 Packaging & Processing Innovation & Design Awards (PIDA) for an innovative solution that promises to fight the War on Waste.

Their Bulk Redemption Terminal (BRT) (formally CSS) was named finalist for the Design Innovation of the Year Award (Beverage Category) and the 2018 Sustainable Packaging Design Award for Machinery/Equipment.

The BTR automatically sorts, identifies and counts container types for recycling depots – all to help increase the uptake of recycling under the Australian Container Deposit Legislation (CDL) scheme.

The system is a premier example of the Internet of Things (IoT) in practice; container data is sent to the cloud for a faster processing and customer refund process, as well as historical reporting and greater probity of information across multiple sites.

It is one of four smart solutions developed by SAGE and sister company digital transformation consultancy Nukon to improve long held challenges experienced by the recycling depot industry. Challenges such as long wait times for customers returning containers, and theft and poor count accuracy due to manual counting and sorting methods.

Until now, technology alternatives to the manual counting method have also been limited; the European-made reverse vending machines on the market only accept and scan containers with intact barcodes – and one at a time. Anything slightly damaged or with no label cannot be refunded.

CDS Executive Chairman Brett Duncanson said years of experience in the industry had prompted CDS to find an alternative solution.

“We knew manual sorting was a pain point in the customer process and other technological solutions weren’t quite hitting the mark,” he said.

Counting and sorting solutions

The automatic Vision Counting & Sorting System (CSS) and display screen showing container count and refund data in real-time.

The PIDA award nominated ‘BTR', the ‘Smart Wall’, the ‘Smart CAGE’ and the ‘Input Station’ are each designed for specific use: from recycling depots, through to public spaces or at public events.

While SAGE delivered the BTR controls system, conveyor lines and vision system in partnership with UniSA, Nukon took care of the IT and customer-facing solutions.

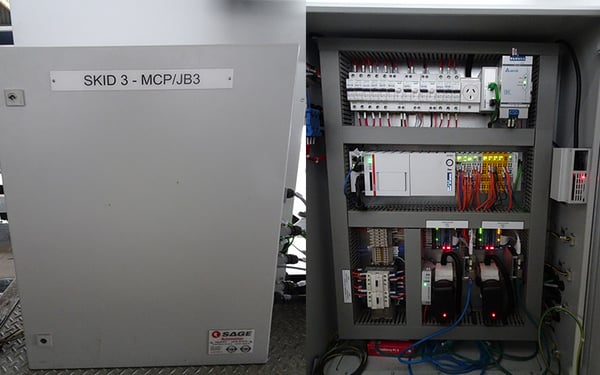

The BTR has five skids with 26 conveyors and a central vision system camera which identifies each item and sorts them using a smart algorithm.

The solution also harnessed a range of vendor and open source technologies. The Nukon customer-facing solution used Single-Board Computers, Amazon Web Services (AWS) and Encryption, while the SAGE control system solution used Beckhoff control and NORD VSDs.

“What’s unique about this project,” SAGE Group CEO Adrian Fahey said, “is how we’ve brought the worlds of IoT, digitisation, control systems and research together to come up with something highly novel and fit-for-purpose”.

“As data becomes more pertinent across manufacturing, transport, operations and business, we see this collaborative approach as the gold standard. We’re bringing together industry and researches’ best minds to deliver the best thinking,” Mr Fahey said.

“But it’s also about encouraging our clients to collaborate more between their IT and operational departments as this is where the biggest gains will be found.”

Greater quality for manufacturers

Combinations of the vision technology, sorting system and/or IoT data network have the potential to bring facilities faster and more accurate quality processes and data probity – at low implementation and operating costs.

“What’s exciting here is how the technology were using, like single-board computers and cloud-based IT infrastructure, is cheap to implement and run,” Mr Jolly explained, “We can set up 5-6 devices for less than cost of a desktop computer.”

The fact that the customer-facing solution was developed and deployed as Platform as a Service (PaaS), also reduces IT infrastructure and data hosting costs.

“We’d never be able to do this with traditional technologies so this shows how the IoT is changing our world – from manufacturing to recycling and beyond,” he said.

A basic illustration of the PaaS-based customer-facing solution (CSS = BTR)

Client feedback: This will promote recycling and a reduction in landfill

“The solution has made the returns process quicker and easier for customers, provided probity of information between members of the scheme and it proposes a viable business opportunity for container depots, both existing and new – all to decrease Australia’s landfill,” Mr Duncanson said.

In Australia, South Australia (SA), Northern Territory and New South Wales are currently the only states to adopt Container Deposit Legislation (CDL), which offers a small refund to anyone who returns an empty container.

SA has the lowest percentage of containers-to-landfill in the country – which has been largely attributed to its long running CDL scheme which began in 1977.

The solutions are currently running at the Meringue Avenue Recycling Centre. A full suite of CDS’s solutions will be available to other recycling depots over the next year.

The PIDA award finalists will be announced in May 2018.

Read how all four solutions work in the Nukon case study: IoT provides answer to War on Waste

Photo gallery: take a look at the BTR in action

The old container refund process was slower and less accurate with manual counting and sorting

The old container refund process was slower and less accurate with manual counting and sorting

New process: containers enter the BTR

New process: containers enter the BTR

Automatic sorting begins with separating containers on a conveyor line

Sorting containers in preparation for vision system identification and counting

Containers travel through vision system that identifies container type and even colour.

Five skids house the control system for the BTR

The HMI gives operators control over the BTR

A NORD Variable Speed Drive in the CSS

Powered by IoT, the BTR instantly calculates customer's refund amount and prints to receipt for cash collection.

When a machine stops, it can quickly escalate to calling in external help – sometimes unnecessarily. The Breakdown Checklist is designed to get you back online faster. It will get your team thinking about what caused the breakdown and assess the need for external advice. Download the free checklist here.